|

Level: Intermediate |

In-company course: Yes |

|

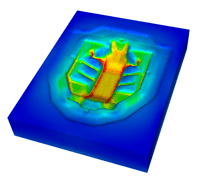

Based on industrial examples, this training will allow you to improve the design of your dies before manufacturing them! You will be able to assess wear, quantify their deformation and predict their premature failure.

Tooling costs represent up to 15% of the total forging cost. Extending the service life of dies is an ongoing challenge for producing more parts using the same dies and lowering production costs. After this course, you will be able to assess wear, quantify the deformation affecting your matrices and predict premature matrix failure. For hot forging, you will master the steady state approach and you will be able to determine the die temperature after a number of forging operations. For cold forging, you will know how to model pre-stressed dies (assembled by interference fit) and optimize shrinkage. Based on industrial examples, this course allows you to improve dies design even prior to manufacture them!

Tooling costs represent up to 15% of the total forging cost. Extending the service life of dies is an ongoing challenge for producing more parts using the same dies and lowering production costs. After this course, you will be able to assess wear, quantify the deformation affecting your matrices and predict premature matrix failure. For hot forging, you will master the steady state approach and you will be able to determine the die temperature after a number of forging operations. For cold forging, you will know how to model pre-stressed dies (assembled by interference fit) and optimize shrinkage. Based on industrial examples, this course allows you to improve dies design even prior to manufacture them!