|

Level : Advanced |

Open course : Yes |

In-company course : Yes |

|

Level : Advanced |

Open course : Yes |

In-company course : Yes |

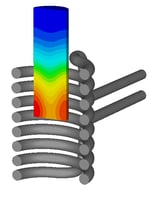

After some theoretical refreshers, you will study how to implement simulated induction heating with a static billet or one that moves through the inductor. You will be able to analyze the influence of the inductor’s design, of the presence of concentrators and test the impact of the various generator parameters. Then you will go on to look at heating for the heat treatment placing the accent on metallurgical aspects, predicting the area that is thermally affected and the use of static inductors or ones with their own kinematics. This way you will understand the thermal and electromagnetic phenomena for optimizing heating conditions.

After some theoretical refreshers, you will study how to implement simulated induction heating with a static billet or one that moves through the inductor. You will be able to analyze the influence of the inductor’s design, of the presence of concentrators and test the impact of the various generator parameters. Then you will go on to look at heating for the heat treatment placing the accent on metallurgical aspects, predicting the area that is thermally affected and the use of static inductors or ones with their own kinematics. This way you will understand the thermal and electromagnetic phenomena for optimizing heating conditions.

Goals:

Duration: 2 days