|

Level : Advanced |

Open course : No |

In-company course : Yes |

|

Level : Advanced |

Open course : No |

In-company course : Yes |

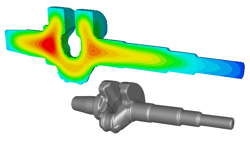

Heat treatment is an essential stage on the way to achieving mechanical and metallurgical properties that are compliant with the specifications for the forging. This course covers the key points in heat treatments applied to forged steels and aluminum alloys. After this course, participants will know how to perform martensitic quenching, carburizing, austenitization, precipitation hardening of aluminum, how to how to work from TTT or CCT diagrams and especially, how to fully analyze all of the computation results (phase, hardness, stress transformation, etc.). This way you will be able to predict the final properties of the parts and their metallurgy, as part of an overall computation comprising forging and the related heat treatment.

Heat treatment is an essential stage on the way to achieving mechanical and metallurgical properties that are compliant with the specifications for the forging. This course covers the key points in heat treatments applied to forged steels and aluminum alloys. After this course, participants will know how to perform martensitic quenching, carburizing, austenitization, precipitation hardening of aluminum, how to how to work from TTT or CCT diagrams and especially, how to fully analyze all of the computation results (phase, hardness, stress transformation, etc.). This way you will be able to predict the final properties of the parts and their metallurgy, as part of an overall computation comprising forging and the related heat treatment.

Goals:

Duration: 2 days