Ascometal, french steel company

Ascometal is a steel company belonging to the Schmolz + Bickenbach group, one of the world’s leading suppliers of custom solutions in specialty steel long products and one of the two biggest companies in Europe working with alloy and high-alloy engineering steel. Based in the North, East, and South of France, Ascometal is a major European player in special steels. It is active on the automotive, bearings, engineering industry, and oil/gas markets.

Ascometal is a steel company belonging to the Schmolz + Bickenbach group, one of the world’s leading suppliers of custom solutions in specialty steel long products and one of the two biggest companies in Europe working with alloy and high-alloy engineering steel. Based in the North, East, and South of France, Ascometal is a major European player in special steels. It is active on the automotive, bearings, engineering industry, and oil/gas markets.

Challenge: validate the dimensioning of a new ingot shape

Ascometal used THERCAST® software to validate the dimensioning of a new 10-ton ingot shape. The simulation was designed to produce a high quality ingot by taking risks linked to solidification (porosity, segregation, etc.) into account.

A study was conducted to compare the principal characteristics of the 10-ton ingot to those of the 5 to 7.5-ton ingots already produced by Asco Industries. The characteristics Ascometal was looking to control were those of segregation, and macrosegregation in particular, in order to guarantee absolutely identical mechanical properties for the parts derived from these ingots. The central porosity of the ingot is also an important criterion in developing a quality final product and accessing the larger-sized parts market.

THERCAST® was used to design the 10-ton ingot according to the following approach:

- Validation of boundary conditions on existing ingots

- Choice of quality criteria

- Consideration of industrial constraints.

.jpg?width=430&name=case_study_ascometal%20(1).jpg)

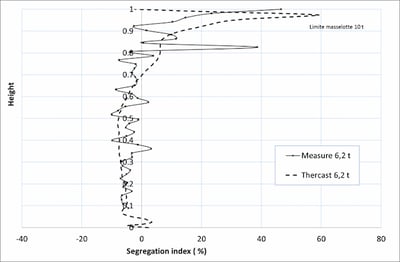

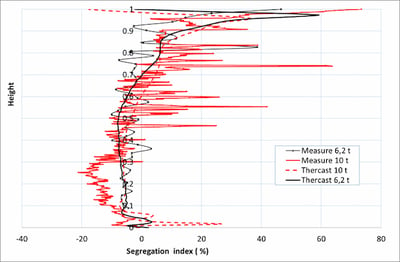

Comparison between the depth measurements of the liquid pool (in cm) and THERCAST® predictions

.png?width=307&name=case_study_ascometal%20(2).png)

Preview of the simulation

Solution: characterize solidification structures

The work consisted of a quantitative characterization of the solidification structures, preliminary work essential to validation, and determining parameters for simulation.

Through previously conducted studies, Ascometal had initial knowledge of existing boundary conditions on the ingots. These previous studies made it possible to confirm the boundary conditions with temperature measurements taken at the top of the ingot. The macrosegregation profiles and solidification structures were also available.

To design the new ingot, different criteria had to be taken into account including the solidification time (shortest possible amount of time), the segregation profile, the Niyama criterion on the axis for porosity, the pressure drop on the axis at the end of solidification, and an analysis of mechanical results. Taking certain industrial constraints into account was essential, maximum height for instance. The parameter mostly studied was the coning of the ingot mold.

« Thanks to THERCAST® software, we were able to confidently propose a new ingot geometry to steel mill crews. The characterizations that were done on the product confirmed these predictions. »

- Joëlle Demurger, Head of the Process Engineering group at Ascometal

La comparaison des résultats entre THERCAST® et les relevés expérimentaux montre que les phénomènes de sédimentation (à l’origine de la ségrégation négative en pied de lingot) sont moins présents sur le lingot 6.2t que sur un lingot plus large (10t).

La comparaison des résultats entre THERCAST® et les relevés expérimentaux montre que les phénomènes de sédimentation (à l’origine de la ségrégation négative en pied de lingot) sont moins présents sur le lingot 6.2t que sur un lingot plus large (10t).

Benefits: improve the quality of the metallurgy

THERCAST® was successfully used to design a new ingot. •The computing time for solidification is correct.

- A location criterion for porosities was defined and computed based on mechanical results. The location agrees with the measurements. The number and size of the porosities have been controlled.

- A negative segregation zone was observed in the larger-sized ingot and this zone is, for the moment, not completely predicted by THERCAST®. This is because of sedimentation (germination and movement of solid grains in the liquid), which is not yet implemented in this model. Research is underway and will, in the short term, improve computing macrosegregation for large-sized ingots. THERCAST® could be used to obtain new levers to act on macrosegregation in ingots.

Simulation with the THERCAST® software helped design a new high quality metallurgical ingot.