Cold forming is a very widely used forming process for its numerous industrial advantages: high production rate, dimensional precision and excellent surface finish, material savings, little or no secondary operations required, improved mechanical characteristics.

Given the production of parts in large series in this area it is important that the fabrication sequence is perfectly calibrated in order to avoid negative impacts on the finished part. The deformation of the metal is able to generate defects on the part or the tool, the simulation makes it possible to be predictive and thus optimize the process.

What are your problems? How can our simulation help you?

To increase your profitability and earn new markets

To have more and more innovative products, without defaults and responding perfectly to the expectations of your customers.

To improve the existing fabrication sequences and solve production problems.

From the most traditional to the most demanding processes, the numerical simulation allows you to produce high added value forged components. Some of the most common cold forged parts include: shafts, hollow shafts, nails, screws, bolts, nuts, rivets, washers and fasteners.

With a simulation software, you become predictive of many things that influence your costs and the quality of your parts :

These criteria can be simulated with our simulation software COLDFORM® for the numerous processes including closed die forming, extrusion, cutting, punching, rolling, heat treatment, machining, and many others. It is suitable for any type of metallic alloy.

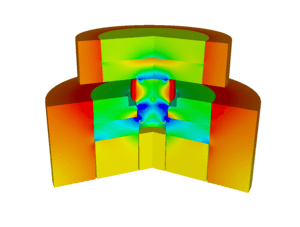

To resist constraints and high rates of current production, the tools used in cold forming require high-performance properties: excellent resistance to fatigue and high wear resistance. The software FORGE® and COLDFORM® enable to predict all these constraints and thus optimize the design, costs and tool maintenance.

To resist constraints and high rates of current production, the tools used in cold forming require high-performance properties: excellent resistance to fatigue and high wear resistance. The software FORGE® and COLDFORM® enable to predict all these constraints and thus optimize the design, costs and tool maintenance.

Tool life can be extended with the analysis capacity of the simulation software. Thermal or thermo-mechanical calculations in tools can be conducted to predict the stress distribution, deformations, wear, temperature and damage to any moment during the process.

FORGE® and COLDFORM® allow two types of analyzes: a fast decoupled calculation in matrices as well as a coupled calculation unique between workpiece and tools. The softwards offer a very large press database: mechanical press, hydraulic press, toggle press and orbital press. complex piloting can also be set. Tools preloaded and mounted on springs can easily be defined.

The simulation accompanies you and helps you in key moments:

Even the most sophisticated developments are often held together by standard parts. The numerous machines do not function without them.

MORE INFO >

For the automotive sector there are often special steering components, brakes, transmissions and engines that are in demand.

Precision mechanisms equip clocks, optical devices, electronic or optoelectronic devices with parts such as spiral springs, nut devices, control screws etc.

Simulate complete sequences to determine the ideal shape and mass of the starting flank and optimize the number of stamping operations.

The stamping sequence was validated by simulation before the start of production leading to the parts being correctly stamped from the first pressings.

“Implementing the COLDFORM® software helped us lower our stamping die design and manufacturing costs by reducing the amount of tools in our stamping process.”

World leader in software for simulation of material forming processes.