From the initial casting to metal solidification, foundry professionals must optimize the production of their parts, slabs or ingots and avoid defects that may appear during the process.

In extremely competitive and ever-changing markets, simulation is now an essential step in the development cycle of high-value cast parts.

What are your issues? How can simulation help you?

To quickly and precisely analyze your manufacturing process from the initial casting until the end of solidification.

To produce high quality components and reduce the prototyping phase.

To understand phase transformations that can occur during solidification and thus, determine the transformation areas appear during casting.

As in the workshop, simulation helps you to act on all the foundry process levers: coatings, cycle times, control of moving part closures, rockers, stopper rods, etc.

As in the workshop, simulation helps you to act on all the foundry process levers: coatings, cycle times, control of moving part closures, rockers, stopper rods, etc.

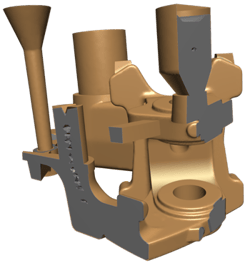

With a tool like our THERCAST® simulation software, you can improve gating systems and optimize feeders. It provides an exact representation of the process parameters (coating, stopper rod action, solidification well, foundry filter, feeder position, etc.)

Take benefits of a true visualization of foundry parts manufacturing since the software simulates ‘Fill and Solidification’ phases at any time and calculation of ‘Fluid Mechanics’ and ‘Solid Mechanics’ are fully integrated.

Finite element modeling is also an ally for innovation. With this software, create innovative ranges of lighter cast parts with the guarantee of flow representation true to the reality of the processes, anticipate macroscopic defects such as shrinkage, porosities, pipes, caved surfaces, piercing or misruns, but also size and test the positioning of feeders, control channels and cartridge heaters.

With THERCAST®, study precisely the foundry processes thanks to the track of particles and inclusions movements, thanks to the prediction of rheological phenomena such as A and V, segregation, solid phase distribution, porosities or residual stresses, but also with the simulation of mold warm-up.

Save time and reduce costs in terms of planning, optimizing and operating your continuous casting process.

Save time and reduce costs in terms of planning, optimizing and operating your continuous casting process.

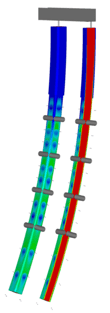

Precisely simulate the metal behavior and other elements of your continuous casting process, as well as all their interactions. It allows you to optimize the casting speed, to avoid hot cracks and ruptures, save energy, enhance safety, and take other measures to improve quality and efficiency while reducing costs.

THERCAST® offers a true visualization of reality by integrating liquid/solid thermomechanical coupling involved in material transformation.

With this implementation, you can study all types of phenomena: ladle and tundish flow, primary and secondary cooling, deformation in contact with rollers and spray-induced cooling.

Simulation helps improve your competitiveness and optimize overall process efficiency. Indeed, you minimize the costs associated with material losses in the high and low zones of the ingots.

Simulation helps improve your competitiveness and optimize overall process efficiency. Indeed, you minimize the costs associated with material losses in the high and low zones of the ingots.

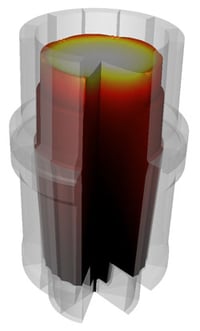

You can save prototyping times: THERCAST® models dynamic air gaps associated with solidification shrinkage.

Detect defects such as shrinkage, distribution of inclusions, porosities, cracks and hot tearings, allows you to improve the quality of your ingots.

Suitable for a wide range of ingot cross-sections or masses, THERCAST® simulates ingot bottom or top pouring. The software incorporates a casting filter module and considers all technological factors such as the presence of refractory materials or coating.

THERCAST® also models turbulent flows and manages all interactions between the metal and the wall of the ingot mold, the slag and the mold flux.

For bottom pouring, THERCAST® validates the geometry and dimensions of the feeding system.

THERCAST® takes into account the elements surrounding the process such as exothermic powder and highlights its impact on the slowing of solidification at the top of the ingot.

Thanks to part- and mold-coupled thermo-mechanical resolution, the software can also anticipate, mold deformation and breakage.

And many more

To contribute to weight lightening of automotive parts made of aluminium alloys, our software integrates a foundry process modeling solution that meets the needs of the largest players in the automotive market, known for their performance requirements.

Thanks to a faithful representation of continuous casting machines configuration, THERCAST® offers a unique and precise solution to meet the challenges associated with profile manufacturing.

With its module devoted to ingot casting, THERCAST® software is the favored partner of steelmakers seeking to optimize their ingot manufacturing processes.

Validate the sizing of a new ingot format.

A 10-ton ingot sizing validation process was implemented and digitally certified before ingot manufacturing using THERCAST® software.

"Thanks to the THERCAST® software, we were able to confidently propose to the steelworks teams a new ingot geometry. The characterizations that were made on the product validated these forecasts."

World leader in software for simulation of material forming processes.