Many plastics manufacturers are adopting numerical solutions to improve the performance of their products through more innovative and greener techniques and materials.

Then, they turned to rheology software to understand and analyze the phenomena related to the injection and expansion of polyurethane foams and other plastics.

What are your issues? How can simulation help you?

To quickly and precisely analyze your manufacturing process from the injection to the cooling phase of the polymer or the expansion of the injected foam.

To analyze your filling and expansion or cooling phases in order to predict the effects of underfilling, shrinking or even the appearance of air gaps.

To study the cycle times of your processes. Define the appropriate parameters to obtain quality parts with a reduced cycle time.

Thanks to simulation, set up your standard injection processes but also more complex processes.

Thanks to simulation, set up your standard injection processes but also more complex processes. Our specialists listen to your needs and support your industrial projects with rheological analysis and quotations always

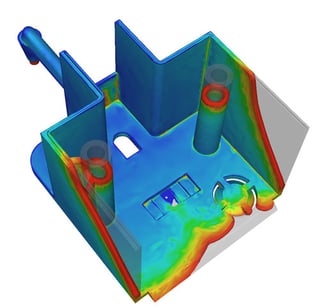

Our specialists listen to your needs and support your industrial projects with rheological analysis and quotations alwaysThanks to predictive simulation, analyze precisely heating maps, pressure evolutions but also foam density everywhere in the part.

Detect molding defects (unfilling, weld zone, shrinkage area,) and aesthetic defaults (setting up of the parting line, orange-peel skin effect) prior to manufacturing.

Then, you can optimize your development phase and validate innovative designs that reduce the weight of your final parts.

And many more

To improve the lifespan of sporting goods and make them more efficient, REM3D® simulates the chemical foaming of flexible and rigid foams.

REM3D® supports you in your innovation projects. From the steering wheel to the pedal or the car seat, the simulation improves the resistance of your foamed components.

REM3D® allows you to control the insulation properties of your devices by simulating, among other things, the density distribution of your materials.

“Accuracy of the simulation results is within the accuracy typical within experimental reproducibility. The REM3D® validation on industrial part shows a realistic flow pattern, predicts minimum fill and allow us to optimize molding conditions (temperatures, gating, venting). Finally, we obtain good density distribution prediction. Indeed, the software takes into account pressure effect (both internal and external) and gravity orientation, both processes parameters important for us.”

World leader in software for simulation of material forming processes.