In markets where the safety of welded assemblies is essential, analysis with TRANSWELD® offers a global and innovative solution to anticipate welding defects.

Our simulation software integrates multi-physical models to simulate the real behavior of the metal in the liquid/mushy state to perform a complete analysis of the material evolution.

TRANSWELD® also makes it possible to study the microstructure of the solid state assembly. Then, you ensure the conformity of your welded part without going through the prototyping stage.

Our software is 100% predictive. It allows you to observe your welding processes numerically by applying real conditions. For example, you can visualize the heat source movement during the simulation of laser welding or arc welding.

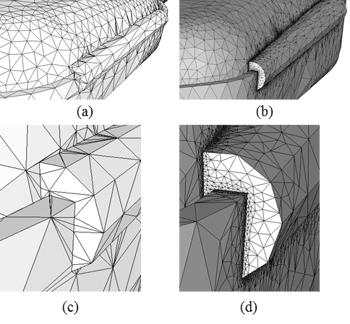

Illustration of automatic remeshing: the initial mesh (a,c) of the part is going to be refined in the area where the filler metal will be fed (b,d)

Illustration of automatic remeshing: the initial mesh (a,c) of the part is going to be refined in the area where the filler metal will be fed (b,d)

TRANSWELD® benefits from all the research and implementations available in other Transvalor suite software.

TRANSWELD® benefits from all the research and implementations available in other Transvalor suite software.

This allows you to prototype your entire product: from the manufacturing of your parts (forged or cast) to the final assembly by welding.

You control each stage of your process and can analyze potential defaults at any time during the forming of your part. By importing your previous forming steps made in FORGE® software (simulation for forging processes) or THERCAST® software (for foundry processes) in TRANSWELD®, you can study the conformity of your part in real conditions.

When solving the computations, TRANSWELD® will take into account the stresses and risks arising from the steps before your welding. You will be able to anticipate the overall behavior of your assembly.

Predict, qualify, and quantify defects of the final part with the most accurate, and fastest software available on the market. Mistakes are made on the computer only, not in production.

In the automotive industry, assembly technologies have become increasingly precise and robust. TRANSWELD® is an accurate technological help for welders to carry out processes that comply with industrial standards of this sector.

Welding metal parts and assemblies for the construction industry requires meeting important requirements. TRANSWELD® helps you define the best welding sequence to obtain welds with excellent metallurgical properties and able to withstand the expected mechanical stresses.

Welding applications have to be adapted to the various steels used in the manufacturing of pipelines, but must also be resistant to the challenging environments that the Oil & Gas sector implies. TRANSWELD® allows the simulation of these different conditions to optimize assembly processes.

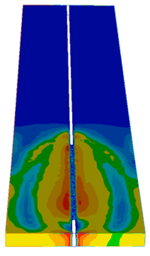

Take independently into account each element of the welded assembly to visualize the physical part generated by the welding.

Thanks to its self-adapting anisotropic meshing during the computation, obtain accurate results and better reactivity.

At macroscopic scale, observe the metal behavior during phase changes and the mechanical stresses generated by the process.

World leader in software for simulation of material forming processes.