In extremely competitive and constantly evolving industrial markets, the forging process has become a critical stage in the development of high-value forged components.

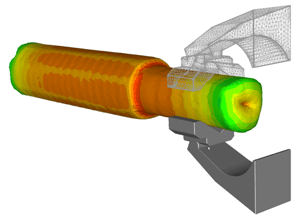

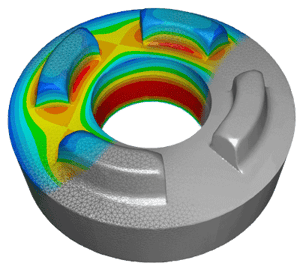

Simulation now plays a major role in supporting forging process design and optimization by enabling engineers to virtually represent metal deformation under a wide range of forming conditions.

By modeling thermo-mechanical and metallurgical phenomena throughout stamping, closed-die, and open-die forging processes, simulation provides a powerful lever to improve process understanding, reduce trial-and-error, and enhance innovation and competitiveness.

What are your issues? How can simulation help you?

To detect defaults such as folds or cracks upstream and to guarantee a good resistance against mechanical stresses thanks to optimum corroyage and fiberizing.

To design first-time-right products and thus reduce the number of trials / errors and limit the machine occupancy rate during the prototyping phases.

To save on quantities of material used, increase the tool life and optimize the number of frappes for each forging sequence.

From the most traditional to the most particular processes, numerical simulation allows you to produce forged components with high added value.

From the most traditional to the most particular processes, numerical simulation allows you to produce forged components with high added value.

With a simulation software, you become more predictive on various elements that get influence on your costs and the quality of your parts:

All these elements concern our FORGE® simulation software and are applicable for a large number of forging processes (closed-die forging, open-die forging, flat and long products rolling, ring rolling, shape rolling, cross-wedge rolling, electrical upsetting, shearing, sheet metal forming, cold forming, etc.).

It is suitable for any kind of metallic alloy.

With simulation, you will be able to:

With simulation, you will be able to:

Simulation has a positive and significant impact at multiple stages of your activity:

And many more

FORGE® is used by the largest manufacturers of forgings in the world for the automotive industry.

FORGE® is used by key producers worldwide to design engine parts such as pressure disks or fan disks or fans, landing gears, fuselage parts, etc.

Our simulation software is an essential and strategic tool for the development of medical devices with high added value.

Confirm the technical feasibility for the implementation of two hundred ASTM 105 steel parts by shape rolling.

Validate numerically the ring rolling process of steel rings before production launch of the ordered lot.

« The obtained results confirm that the use of FORGE® for the numerical simulation is definitely a good business card for our company, also talking on pure commercial terms. It allows us to differentiate in a very positive way, anticipating customers’ objections and offering a sensible cost reduction and quality increase. »

World leader in software for simulation of material forming processes.