cross-wedge rolling

Cross-wedge rolling, like shape rolling, is a process used to produce preforms, most commonly employed in the automotive industry. This rolling technique combines high productivity, long die life and good material efficiency (no waste produced). Simulation of this preform process allows determining the distribution of state variables (temperature, strain, and stress). Incorporating these values in the simulation of a subsequent forming process increases the accuracy level of the entire process chain simulation.

Simulation of cross-wedge rolling by rolls - Courtesy Lublin University of Technology.

FORGE® features a precise contact algorithm and a temporal integration scheme for updating the coordinates naturally adapted to rotation which render the simulation of cross wedge rolling highly accurate. Resorting to tricks such as forcing component rotation or blocking its displacement is thus unnecessary. Simulation, in this case, becomes a real predictive tool which can be used to fine-tune the process.

Simulation of skew rolling - Courtesy Lublin University of Technology

Benefits of Predictive simulation

FORGE® allows an accurate prediction of:

- The geometry of the preform at the end of the cross wedge rolling stage,

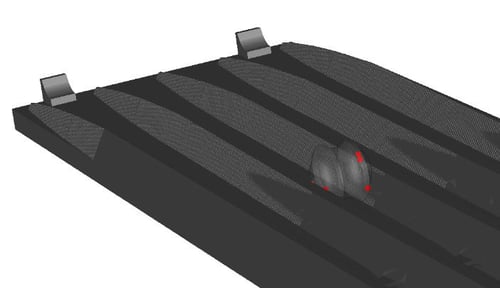

- Presence of folds/laps or other defects

- All the state variables, like for example the equivalent strain in order to take it into account in the subsequent operations

- Torques and loads to apply on the rolls

Folds detection (in red) during the skew rolling

features of FORGE® for cross-wedge rolling

- Real kinematic applied on the rolls

- Volume conservation of the preform during the simulation thanks to an appropriate rotational update scheme

- Easy prediction of flaws including Mannesmann effect

- Chaining with subsequent forming operations

Cross-wedge rolling simulation - Courtesy Lublin University of Technology

Case study - Cross-wedge rolling and skew rolling

The conference presents the results of numerical simulations of several rolling processes made by Lublin University of Technology (Poland): such as cross-wedge rolling of a stepped shaft, cross-wedge rolling of pre-forms, cross-rolling of balls, helical-wedge rolling of balls and ball pins, rolling on a numerically controlled skew rolling mill. The results from numerical simulations were compared with the results of experimental tests that verify them, both in laboratory and industrial conditions.