REM3D® is a finite element simulation software dedicated to plastic injection processes and especially for polyurethane foam molding. Optimize your processes to increase your productivity and improve the quality and the in-use properties of your parts.

Based on a local density map, REM3D® provides reliable answers for the prediction of parts resistance as well as insulating, noise and/or comfort properties.

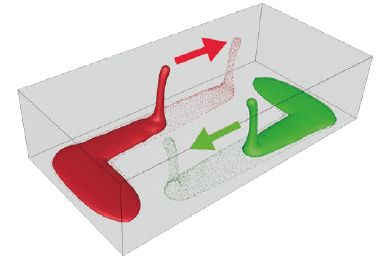

Simulate a ‘dual foam’ pouring and observe the transition zones between foams of different rigidities.

Dual-foam pouring with moving injectors

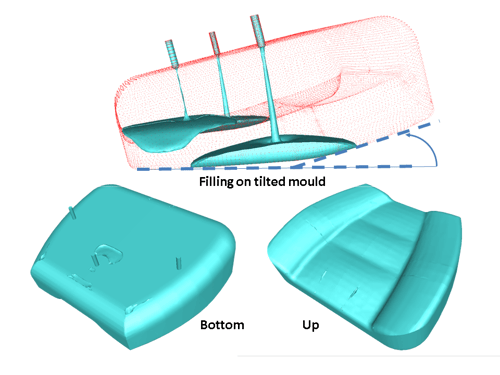

Taking into account "mold tilting" translates realistic process conditions to be as close as possible to reality. The integration of functionalities such as automatic mold tilting or the impact of gravity on the melt flow allows to analyze the real conditions of your processes to guarantee the homogeneity of your parts. The study of the positioning of the injectors limits the presence of defaults.

Seat cushion molding with mold tilting

Thus, you get reliable predictions concerning the resistance of your parts but also the insulating and comfort properties of the foams.

For plastics with fibers, REM3D® determines the fibers orientation during the filling stage and after cooling. You can easily observe the orientation tensor during the injection phase in an ellipsoid form and highlight the orientation from core to skin.

Thanks to a fully automatic adaptive technology for anisotropic mesh (AAA remeshing : Automatic Anisotropic Adaptative), you obtain results of a very high accuracy without being an expert in meshing techniques. This technology guarantees an extreme sharpness when showing the fluid flow. Furthermore, as the re-meshing stage is fully integrated into the computation, it is parallelized which brings to very competitive calculation time in 3D.

This unique automatic re-meshing capability enables to observe very sharp defects or complex phenomena such as "jet buckling" or "fluid buckling" which are undetectable with 2.5D software-type, but critical for the final appearance of the components.

With REM3D®, validate and optimize your most complex injection processes.

Automatic mesh adaptation during the calculation along the jet

The REM3D® user interface allows you to easily model your process environment and start simulating your injection processes quickly. You can also access your machine properties to faithfully configure your virtual environment and obtain better results.

REM3D® also offers unlimited access to pre- and post-processors. The simulation results can be analyzed from as many computers as necessary in order to facilitate exchanges between your experts and speed up the resolution of your issues.

To improve the lifespan of sporting goods and make them more efficient, REM3D® simulates the chemical foaming of flexible and rigid foams.

.jpg?length=500&name=industrie_automobile1-(1).jpg)

REM3D® supports you in your innovation projects. From the steering wheel to the pedal or the car seat, the simulation improves the resistance of your foamed components.

REM3D® allows you to control the insulation properties of your devices by simulating, among other things, the density distribution of your materials.

“Accuracy of the simulation results is within the accuracy typical within experimental reproducibility. The REM3D® validation on industrial part shows a realistic flow pattern, predicts minimum fill and allow us to optimize molding conditions (temperatures, gating, venting). Finally, we obtain good density distribution prediction. Indeed, the software takes into account pressure effect (both internal and external) and gravity orientation, both processes parameters important for us.”

Test your designs, visualize the flow of the material front and detect any filling defaults. You can thus adapt the design of your molds.

Reduce the quantity of injected PU foam by determining the best mold balance and the initial deposit mass according to the targeted final density.

Analyze the influence of material and process parameters on your final part thanks to a fully coupled resolution that includes an automatic anisotropic adaptive meshing.

World leader in software for simulation of material forming processes.