For all of your operations (stamping, twisting, driving in, casing, rolling, indenting, blanking) as well as for all of your components (case middle, bezel, crown, back cover, links, buckle-clasps…), whatever the material may be (stainless steel, titanium, brass, precious metals).

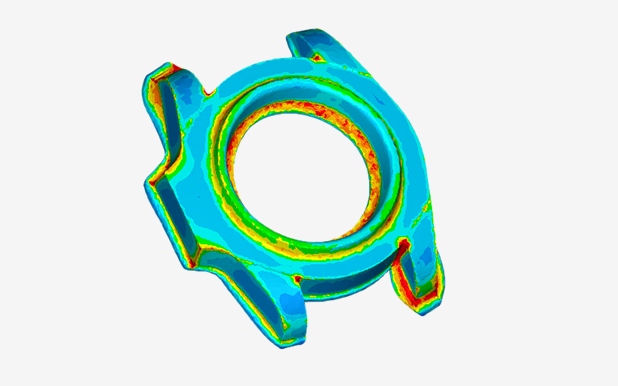

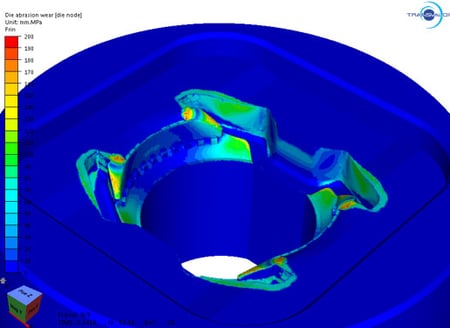

Simulation of the stamping sequence of a buckle. Courtesy of Boucledor