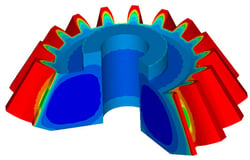

Induction heat treatment simulation provides comprehensive information about temperature gradient from surface to core and also the location of areas where phase transformations occur.

SIMHEAT® can monitor the impact of current frequency, coil geometry and even concentrators’ location within the heat affected zone. Material modelling considers electrical and magnetic properties that are temperature-dependent.

SIMHEAT® is perfectly dedicated to induction hardening with :

A multi-physics approach to capture ‘mechanical-electromagnetic-metallurgical’ phenomena

Monitor inductors & concentrators in motion to image rotating parts and induction equipment (e.g. case hardening of a crankshaft)

Up-to-date modelling of the generators that adjusts current intensity and frequency to maintain prescribed nominal power values

Prediction of heat affected zone and metallurgical transformations to identify austenized areas prior to quenching

Local mesh adaptation based on the temperature penetration depth

Simulation of induction heat treatment of a crankshaft: temperature evolution

Simulation of induction heat treatment of a crankshaft: temperature evolution

Local phase transformation with appearance of austenite

Local phase transformation with appearance of austenite

SIMHEAT® has a lot of interesting features:

SIMHEAT® has a lot of interesting features:

Full compatibility with JMatPro® database

Generation of Kirkaldy-based TTT diagram for low-alloy steel grades

Import tailored CCT diagram in text format

Carburizing: offset of transformation kinetics as a function of carbon rate

Age hardening based on Shercliff-Ashby models for heat-treatable aluminium alloys

READ MORE >

Distortion models applicable to any kind of metal including aeronautic alloys

Material sensor tracking to plot characteristics over processing

Predict, qualify, and quantify defects of the final part with the most accurate, and fastest software available on the market. Mistakes are made on the computer only, not in production.

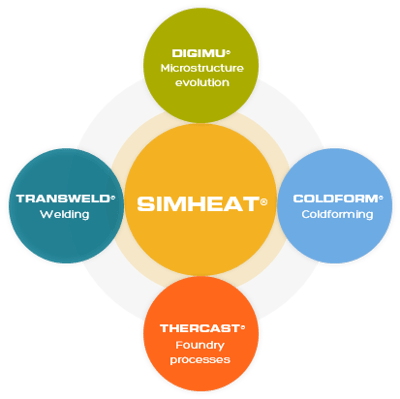

SIMHEAT® can be used as a standalone solution or in combination with Transvalor software. The perfect interoperability guarantees seamless results transfer from one solution to another.

It can be used with:

THERCAST®: for the simulation of foundry processes, continuous casting and ingot casting.

COLDFORM®: for the simulation of cold forming processes.

TRANSWELD®: for the simulation of welding processes and assembly.

DIGIMU®: for the simulation of microstructural evolution.

All the capabilities and functionalities of SIMHEAT® are also integrated in our FORGE® software, dedicated to the simulation of hot, semi-hot and cold forming processes.

And many more

.jpg?length=500&name=industrie_automobile1-(1).jpg)

Simulation is commonly used in the automotive industry to act on the final characteristics of parts (weight, ductility, hardness and resistance).

To improve the performance and resistance of aeronautical parts, simulation makes it possible to predict metallurgical transformations of metals.

.jpg?length=500&name=industrie_me%CC%81dical-(1).jpg)

Heat treatment processes can be simulated to optimize mechanical properties and ensure the safety of surgical implants during their application.

Validate the induction hardening process for the manufacturing of steel bearing rings.

« The solution is predictive because the parameters of the generator are used as they are as input data in the simulation for predicting the metallurgical properties of the part. »

Clear and objective reasons to distinguish ourselves.

Simulate all your thermal cycles thanks to models for heating, quenching, annealing / tempering, carburizing, nitriding, and controlled cooling. SIMHEAT® predicts phase changes, hardness, residual stresses and distortions in your parts.

TTC and CCT diagrams are generated for low alloy steel grades based on their chemical composition and initial grain size.

Thanks to inverse engineering the SIMHEAT® automatic optimization module, identify the precise values of your process parameters.

World leader in software for simulation of material forming processes.