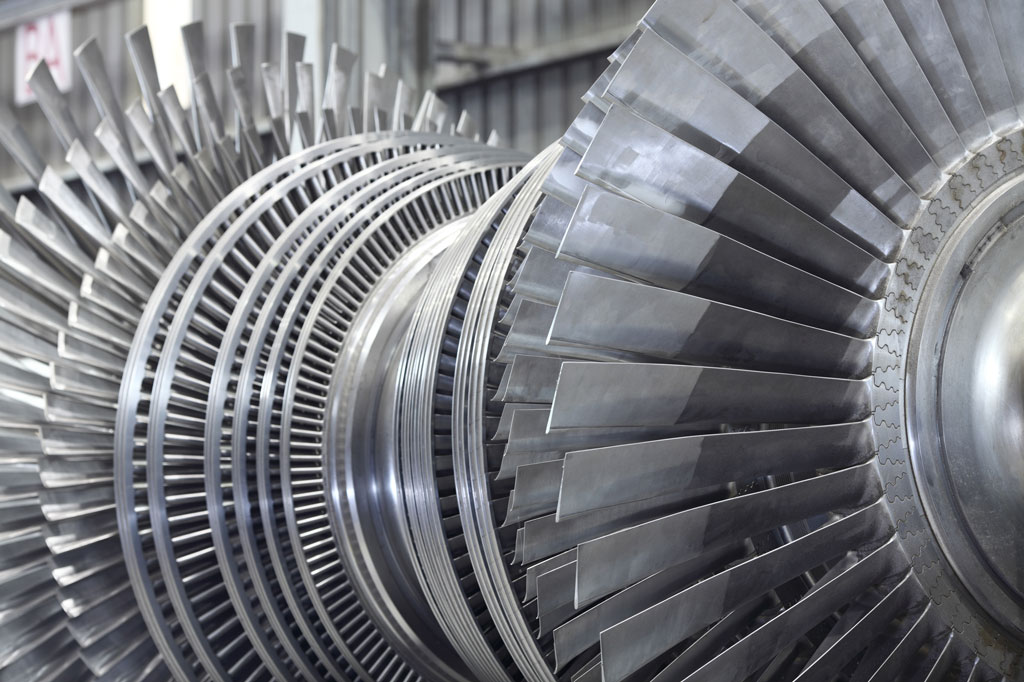

FORGE® is successfully used by various players of the energy sector. A large range of components can be simulated including rotors, forged shafts, pinions and gears, but also seamless tubes for the oil and gas sector and rolled rings for the wind sector.

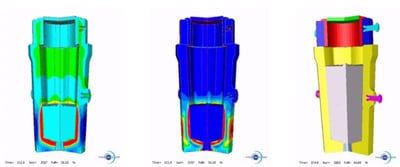

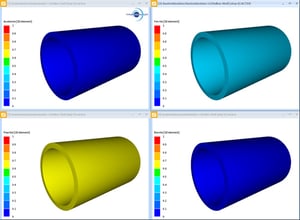

For open-die forging, the software has unique functionalities to simulate processes such as upsetting, cogging, etc., and for seamless tubes it simulates hot rolling with mandrel. FORGE® has a two-mesh algorithm to significantly reduce computation time for processes with incremental deformation.

Thanks to a ‘Multi Pass File’, all the movements of the part imposed by the manipulators, displacements and rotations, can easily be setup, and the simulation of all the steps is handled in a unique launch.