Welding engineers seek to understand thermo-mechanical phenomena occurring during welding processes.

Thanks to simulation, they can obtain this information upstream of the production phase, allowing them to optimize their welding operations and choose the appropriate materials.

What are your issues? How can simulation help you?

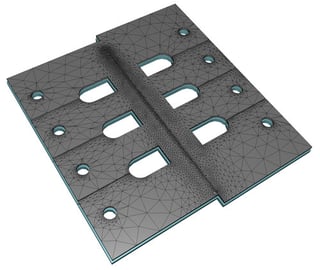

To ensure the welded assembly conformity by highlighting the residual stresses of the various elements, but also to observe the deformation due to the welding of the assembled objects.

At macroscopic level, to observe the metal behavior during phase changes and to study the metallurgy of the solid at the bonded interfaces.

To define your welding process parameters and choose the best compromise in order to combine quality and savings.

Simulation is a competitiveness lever. It allows you to study welding processes quickly and without great expenses.

Simulation is a competitiveness lever. It allows you to study welding processes quickly and without great expenses.

Whether you are a process specialist with or without filler material, you can observe the behavior of your welded assembly using a simulation software such as TRANSWELD® and then, through the prototyping, validate the best results obtained with simulation.

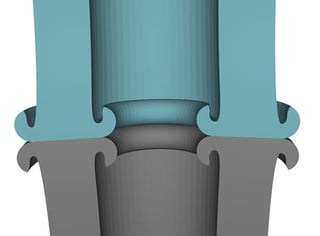

Through scientific models implemented in simulation software, modeling makes it possible to anticipate the shape of the welding burr for processes such as friction or electrical welding, and also for the deposition and shape of the weld bead for arc or laser welding.

In order to avoid risks of rupture of your assemblies, simulation makes it possible to highlight defects such as unfilling or excess, hot or cold cracks but it also allows you to follow the evolution of the impact of the weld on the joined elements and thus, anticipate the risks of assembly rupture. All these features ensure that you are line with established compliance and offer secure assemblies.

Thanks to simulation, you can also deeply explore the material by studying solid metallurgy.

Thanks to simulation, you can also deeply explore the material by studying solid metallurgy.

And many more

.jpg?length=500&name=industrie_automobile1-(1).jpg)

In the automotive industry, assembly technologies have become increasingly precise and robust. TRANSWELD® is an accurate technological help for welders to carry out processes that comply with industrial standards of this sector.

Welding applications have to be adapted to the various steels used in the manufacturing of pipelines, but must also be resistant to the challenging environments that the Oil & Gas sector implies. TRANSWELD® allows the simulation of these different conditions to optimize assembly processes.

The assembly of parts and sheets for the construction of ships has to meet very high requirements. TRANSWELD® makes it possible to improve these applications by calculating, for example, fatigue or sizing of parts.

World leader in software for simulation of material forming processes.