Simulate the polyurethane foam injection and molding process

Benefits of predictive simulation

REM3D® competitive features for PU injection molding

Simulate the Polyurethane foam injection and molding process

Simulation helps to reduce the length of prototype phases and accurately define injection parameters for any part manufactured from polyurethane foam.

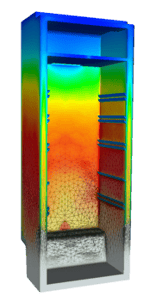

For open or closed molds, simulation software gives the user the possibility to validate the inlet position, foresee the position of the parting line or define the initial mass of foam to be injected in order to obtain the desired final density.

Benefits of predictive simulation

REM3D® provides an accurate prediction of:

- Incomplete filling areas

- Foam evolution during the expansion phase

- Evolution of mold temperature

- Placement and type of defects such as shrinkage or overlap areas

- Final properties of your component, such as density or conductivity. These results can be determined for each point of the part and depend on the stresses applied to the foam during filling (pressure, shear, etc.)

- Minimal mass to be injected

- Cycle times

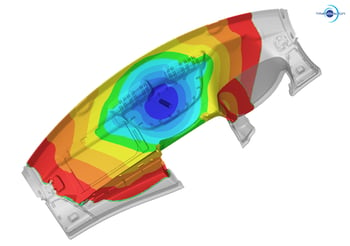

PU foam molding for the manufacturing of dashboard

REM3D® competitive features for PU injection molding

- Easy setup of all process parameters such as inlet position and trajectory, initial injected mass, event positions, cycle times, mold opening management, material of each component, etc.

- In order to obtain accurate, trustworthy results, the software takes “dual foam” filling and “mold tilt” management into account.

Simulation of "dual foam" filling

- Inlet trajectory management. Each injection can be observed separately for better analysis.

- Foam characterization thanks to our Transfoam module, for a complete setup.

- Study of the impact of mold dimensions on the final part.

- Complete simulation of the polymerization reaction: exothermic phase of the reaction, gelling, and the effects of temperature on the polymerization reaction.

- Complete simulation of the foaming reaction: quantity of CO2 created, expanded foam volume depending on the quantity of gas generated, effects of temperature on the foaming reaction, taking physical stresses such as pressure or shear into account for the final state of the foam in order to predict areas of overdensity.