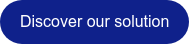

Boucledor, specialized in Fine Watching

Founded in Geneva (Switzerland) in 1965, Boucledor SA is active in the design and the manufacturing of buckles and clasps for Fine Watchmaking as well as luxury jewelry. With an experience and know-how developed over the last 50 years, Boucledor has developed products of exceptional quality and successfully responds to the most demanding requests of its customers.

Founded in Geneva (Switzerland) in 1965, Boucledor SA is active in the design and the manufacturing of buckles and clasps for Fine Watchmaking as well as luxury jewelry. With an experience and know-how developed over the last 50 years, Boucledor has developed products of exceptional quality and successfully responds to the most demanding requests of its customers.

Challenge: optimize the stamping process

Boucledor manufacturers stamped parts in small and medium-sized production runs. The Fine Watchmaking sector must face specific challenges involving the use of precious metals. That is why it is essential to control the flank’s weight to the gram. The software challenges are quite numerous:

- Master the design of tooling (direct design of the preform tooling)

- Definition of the flank (starting preform) without empirical physical testing (optimization of the material used as alloy and time for tooling manufacturing)

- Optimization of the stamping sequence (improvement of stamping throughout time)

- Optimization cost of the tooling

- Control the HV hardness of the parts in case of “elastic” parts

- Master the tooling robustness (possibility to make preventive maintenance)

- Reverse engineering (in case of old tooling)

Simulation of stamping operations from roughing to finishing

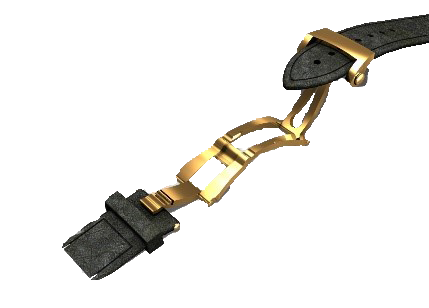

Tooling design

Solution: simulate the complete sequence

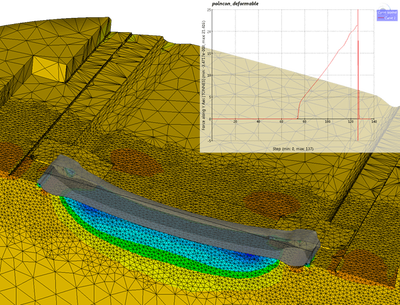

The entire CAD model (parts and tooling) as well as the internal technical data (material record, lubrication conditions) are imported into the COLDFORM® program in order to simulate the projected operational sequence.

The "automatic chaining" function calculates the sequence in its entirety from the 1st station to finishing without needing the user’s input. This produces considerable time savings.

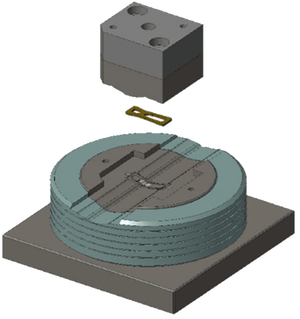

The simulation can easily draw attention to the underfilled areas. The flank’s shape and its interior cutting can therefore be optimized to guarantee complete filling without generating too much material excess.

Also, being aware of elastic phenomena is essential. The calculation with a deformable die makes it possible to quantify the elastic deformation of the tooling and consequently to better control the final geometries. This ensures strict tolerances and limits repeating the production of the final part.

Fill rate at the end of the operation

.jpg?width=400&name=case_study_boucledor%20solution%20(2).jpg)

Constraint calculation in stamps and prediction of the strike force

Benefits: control stamping and manage costs over the long term

- Complete simulation of stamping operation «chain» - Numerical validation of the filling rate

- Numerical validation of tonnage

- Numerical validation of tooling

- Numerical validation of the final sequence (including the annealing and lubrication operations)

- Validation of the tooling’s mechanical stress

- Preventative maintenance plans

The COLDFORM® software now contributes to the validation of the manufacturing procedures at Boucledor.

Implementing the COLDFORM® software helped us lower our stamping die design and manufacturing costs by reducing the amount of tools in our stamping process. Thanks to the software’s upstream analysis and simulation, the stamp maker can now directly compare theory with practice during stamping chain design, which makes it possible to avoid any deviation of our process and translates to major time savings. We were also able to extend the life of our stamping tools (punches, cores, matrices, etc.) by reducing the amount of breakage, by better distributing the stresses on our tools.

- PES Benoît, Head of Stamping and Mechanics

- CHAVES André, Expert Stamp Maker BSA