electrical upsetting

Electrical upsetting is a manufacturing process that consists in passing a high-density electric current through conduction on a metal workpiece. The heat produced by the electric current makes it possible to deform the material to the desired shape.

At Osnabrück University (Germany), Transvalor and LUW IFUTEC, the institue of forming technologies, collaborate to develop FORGE® software and machine technology for the electrical upsetting process.

Electrically assisted forming

Benefits OF Predictive simulation

Numerical simulation helps to optimize your process and find the right parameters to obtain optimal preforms for forging:

- Define real parameters easily

- Conduct sensibility studies to check the influence of inputs on the results

- Find optimal machine settings for your production

FORGE® provides accurate prediction of:

- Thermal data: heating, temperature evolution, etc.

- Electrical data: current density, electrical potential, Joule heating power, etc.

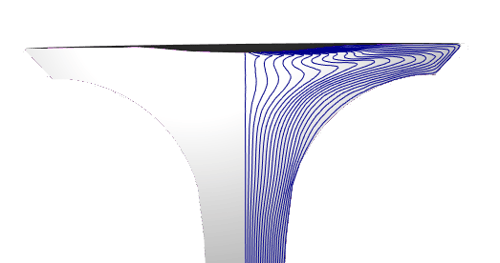

- Effective strain distribution

- Kinematic data: movement of the anvils, direction, height, speed, etc.

- Shape obtained during the preform

Grain flow obtained after the final forging operation of engine valves

FORGE® features for electrical upsetting

- For multi-body systems, contact resistance plays a major role in the outcome. Electrically Assisted Forming is highly sensitive to contact conditions. For this reason, a special electrical contact resistance has been implemented in FORGE®.

- The FORGE® electro-thermo-mechanical solver lets you to simulate electrical upsetting by considering all phenomena (electrical, heating and mechanics).

- Automatic multi-material remeshing is performed at the head and near the contact with the clamp where most deformation occurs.

- The electrical upsetting process can be part of a series of applications that you can simulate with a unique software package (more details in the video below).

CAse study: electrical upsetting applied to engine valves manufacturing

The aim of this presentation is to demonstrate that FORGE® is an essential tool to master all stages of the manufacturing process of a high-tech product, such as the inlet and exhaust valves.

![]() In the video, click on this icon to activate the subtitles in English, French or German.

In the video, click on this icon to activate the subtitles in English, French or German.