Ring ROlling process

.png?width=250&name=FORGE_ring-rolling%20(3).png) Ring rolling is used to produce seamless rings, for example for the aerospace industry (engine components) and the energy industry (windmill parts). The automotive industry also employs ring rolling to manufacture bearings, most often at ambient temperature.

Ring rolling is used to produce seamless rings, for example for the aerospace industry (engine components) and the energy industry (windmill parts). The automotive industry also employs ring rolling to manufacture bearings, most often at ambient temperature.

FORGE® software allows the precise simulation of ring rolling of conventional and shaped rings.

benefits of Predictive Simulation

FORGE® allows an accurate prediction of:

- Geometry of the rolled ring at every moment of the process, final shape of the ring and correct filling for shaped rings

- Defects (underfilling, fish tail, ovalization, excentricity)

- Temperature distribution, deformation ratio and required reheat

- Microstructure (grain size, structure, grain growth, etc.)

- Efforts and torques generated onthe cylinders

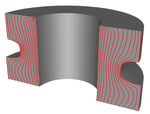

.png?width=400&name=FORGE_ring-rolling%20(4).png)

Radial-axial circular rolling simulation with FORGE® software

Competitive features of FORGE® for ring rolling

- Accurate temperature, strain, stresses and state variable calculation

- High parallel scalability for optimal CPU time speed-up

- Dedicated technic for ring rolling dies representation to increase accuracy and reduce computation time

- Specific mechanical approach Arbitrary Lagrangian Eulerian (ALE) method

- Microstructure prediction with available data for aerospace and energy industry materials

Ring rolling of a waspaloy shaped ring for the aerospace industry, with microstructure prediction. Average diameter (µm) is represented on the ring itself and plotted on 3 sensors.

- Real kinematic applied for refined process simulation and centering rolls considered

- With the “Carwin-like” mode, manage rolling curves and kinematic control (with return loops) in accordance with actual rolling mill control

- Possible coupling with an external piloting module – User Piloting External Module (UPEM) – to reproduce the real shop floor complex kinematic (see video below)

Ring rolling of a low alloyed steel shaped ring used as a bearing in a windmill. This simulation was carried out with the UPEM module which, in that case, was fed by Muraro, a press and ring rolling mills producer and a Transvalor customer.

FORGE® RIng ROlling Module

If you only want to simulate ring rolling applications and not other hot forging processes, the FORGE® Ring Roling module is made for you. Your license is made up of a given number of tokens to simulate forging operations and a double of tokens exclusively for ring rolling operations.

If you only want to simulate ring rolling applications and not other hot forging processes, the FORGE® Ring Roling module is made for you. Your license is made up of a given number of tokens to simulate forging operations and a double of tokens exclusively for ring rolling operations.

More info

Case study - validate a ring rolling process with simulation

In order to supply two hundred A105 steel shaped rings to a new customer, the Italian company FELB Srl used FORGE® software to achieve several simulations to confirm the technical feasibility of project.

In order to supply two hundred A105 steel shaped rings to a new customer, the Italian company FELB Srl used FORGE® software to achieve several simulations to confirm the technical feasibility of project.