More accuracy in radiation simulation for foundry processes

Thanks to the work of Transvalor’s scientific developers, the modeling of radiation heat transfer already implemented in THERCAST® simulation software has been significantly improved. Consequently, the impact of radiation is now accurately considered and especially useful when simulating foundry casting processes with clusters or cooling stages.

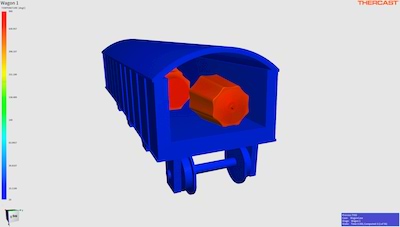

When radiation is involved in a process, heat transfer occurs between bodies and with the environment. These complex exchanges are taken into account by the software. Investment casting or cluster casting of small and medium-sized ingots are typical processes that require this new simulation technology.

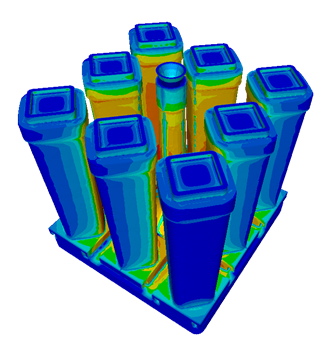

Investment casting of golf head clubs

Temperature in several ingots cast in a cluster

Influence of radiation

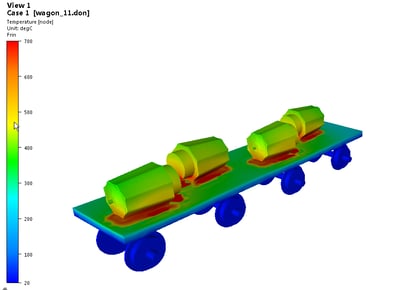

It is essential to consider the radiation at high temperature for its impact on the prediction of defects such as shrinkage or macro-segregation.

This is a very important parameter that impacts the process optimization as self-radiation (or radiation with the surrounding media) affects cooling rates and solidification patterns.

The radiation feature has been available since THERCAST® NxT 1.0. The forthcoming release of THERCAST® NxT 2.0 will showcase an optimized modeling based on an innovative calculation method of the view factors.

Last but not least, this new calculation method is much faster than before and therefore it has a very positive impact on the overall computation time.

Temperature distribution during cooling of steel ingots in a wagon

Watch this video to learn more about heat transfer radiation modeling:

Subtitles available in English and French