Improve the laser welding

To meet the needs of the industry main players, Transvalor is developing by the end of 2020 the first commercial version of its TRANSWELD® software dedicated to welding processes. This solution predicts the thermomechanical behavior of an assembly during the process.

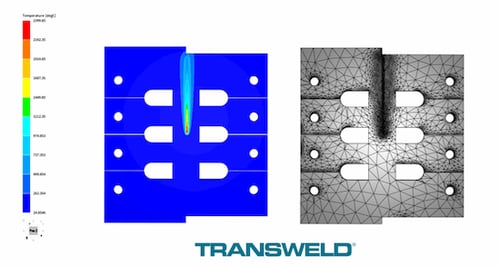

One of the various processes that TRANSWELD® can simulate is laser beam welding. It consists of assembling several metal parts using a laser beam, without filler material. This process, often used in the automotive industry, allows to combine precision, accuracy of the weld and speed. It allows a highly concentrated heat source with a deep penetration and generates less distortion compared to other assembly processes.

STudy and optimize the assembly

At a macroscopic scale, TRANSWELD® analyzes phase transformations in order to detect potential mechanical and metallurgical defects, thus helping you to design quality assemblies.

The software anticipates the distortions and residual stresses that could appear within the assembly; it makes it possible to study the extent of the heat affected zone but also the evolution of the microstructure during the process.

With TRANSWELD®, you also have the possibility to define all the process input parameters (geometry and material of each element, trajectory, beam power...).

Then, thanks to numerical simulation, it is now possible to predict the behavior of an assembly and thus optimize the laser beam welding process.