For the design of your castings, THERCAST® will provide you with valuable support whatever the technology you use: sand casting, shell casting, low-pressure casting, high-pressure die casting, centrifugal casting, tilt casting, investment casting.

Foundry process simulation finally becomes predictive!

As in the workshop, you dress the molds according to the desired type and thickness, you manage the cycle times, you control moving part opening and closing as well as the scales, you control the stopper rods, etc.

A "Filling & Solidification" simulation performed at any time and with a single software application

Casting simulation with THERCAST® software makes it possible to view part filling and solidification from a different perspective.

Indeed, the software makes it possible to account for shrinkage leading to local air gaps, and as such, for any complexities of part cooling in the mold. Thus, the heat exchanges from solidification are fully taken into account. They are determined automatically by the solution and no longer require multiple tests / errors to match reality.

In particular, they are determined by the various mold dressings during shell casting, or by local surface forces during pressure die casting, and by the roughness of the sand in contact with an insert or the lower and upper parts according to the simulated method.

Whatever your technology used, THERCAST® can assist you.

Sand casting

THERCAST® has a dedicated template that simulates the casting of your alloy in a sand mold with inserts taken into account if necessary.

Thanks to its ability to take into account the complex behavior of the solidifying alloy, as well as all the thermal and mechanical interactions between the part and the mold, THERCAST® allows you to predict the final shape of the part, along with any internal defects (shrinkage) and stress distribution in both the part and the mold.

Shell mold gravity casting

THERCAST® has a template dedicated to shell casting.

This will allow you to simulate the casting of your alloy through the various cycles, taking into account changed in heat exchange between the mold and the part through the successive openings and closures of the mold parts and inserts. The dressing and blowing phases, along with insert removal, are taken into account in the simulation of the process. You can simulate reality closely.

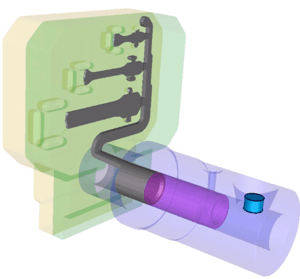

Low-pressure die casting

THERCAST® has a low-pressure die casting-specific template.

All the process phases are simulated: bath pressurization, rising in the mold and holding are perfectly simulated by THERCAST®. Alloy shrinkage during solidification is very well rendered as observed in reality. You can thus optimize your cycle times, mold control and hold time.

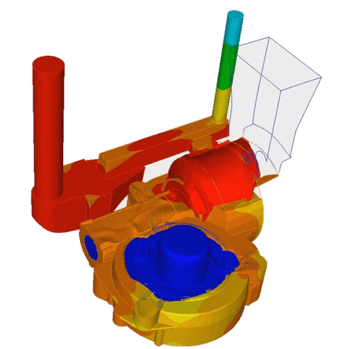

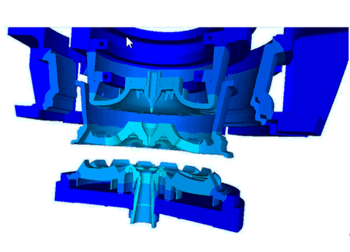

High-pressure die casting

During the high-pressure die casting process, THERCAST®, thanks to its dedicated template, can take into account the pouring phase of the metal into the container by the ladle. Similarly, all the part-filling stages are simulated:

phase 1 - constant-speed ladle filling up to gatings,

phase 2 - filling of the part with speed ramp-up,

phase 3 - piston pressure hold for packing during part cooling.

The dressing, blowing and mold regulation stages are perfectly taken into account by the software.

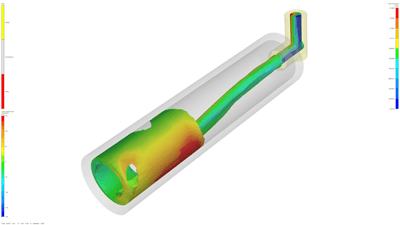

Centrifugal casting

THERCAST® has a centrifugal casting-specific template.

Through these simulations, you are able to perfectly analyze the process filling and solidification phases, which is particularly suitable for molding hollow bodies.

The software takes into account the rotational speeds of the molds and verifies the impact of dosing on final filling.

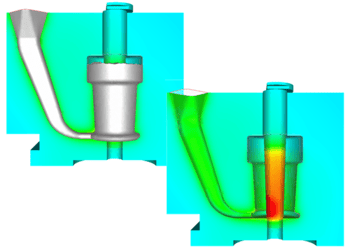

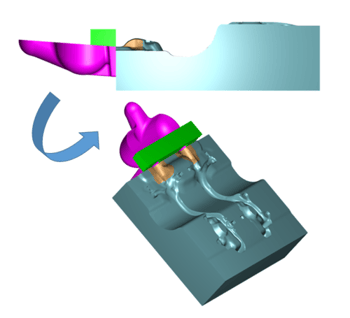

Tilt casting

THERCAST® has a tilt casting-specific template.

This will allow you to fully configure the path and rotational speeds of the mold. The axis and center of rotation are defined without any restrictions. You also have full control over mold regulation, both the cooling runners and the heating cartridges.

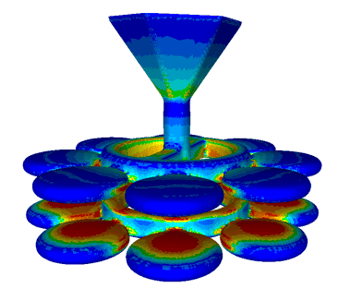

Investment casting

THERCAST® has a dedicated template for investment casting (precision lost-wax casting).

This will allow you to build the shell directly from the surface of the nest. You will be able to simulate casting by taking into account the thermal and mechanical interactions resulting from the self-radiation that occurs during the process. In this way, all the complexity of nest cooling is perfectly described by the software. It is also possible to predict the crystalline structure within the alloy in order to estimate grain orientation in the very core of the part.