Development of the multidirectional forging process

The Cetim forge commission has set up a research group to study the development of the multidirectional forging process.

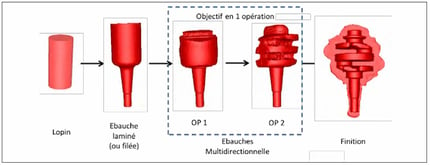

Multidirectional forging is a process which consists in forming a part using transverse kinematics of tooling going in different directions, and in a single step. This type of process makes it possible to obtain preforms with more complex geometries and a better distribution of the volume in the part.

To develop multidirectional forging, the Cetim worked in collaboration with IPH (Integrierte Produktion Hannover), a research institute specialized in production technologies. The IPH based its research on a crankshaft, a part very suitable for multidirectional forging.

The purpose of this work is to improve the design and the production of tools, as well as their lifetime.

Forging sequence of the industrial case - Source : Cetim

The simulation of multidirectional forging of a crankshaft

The main goal of the IPH was to reduce the number of operations and to aim the manufacturing of a crankshaft without burr.

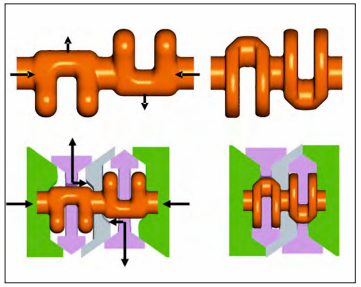

To understand the movements of matter and consider the different kinematics of the tools, a study was carried out with the FORGE® simulation software.

This numerical study made it possible to grasp different elements:

- The forging sequence and tool kinematics

- The complexity of tools

- Thermal aspects depending on the scale selected

- Definition of machine requirements to ensure the forging operation

The feasibility of the process could therefore be validated.

Read the article (in French only) >

Tools kinematics during forging operation - Source : IPH