Simulation of bending processes with FORGE®

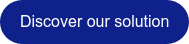

Cold wire bending with three consecutive forming stages. Temperature distribution is shown on the component.

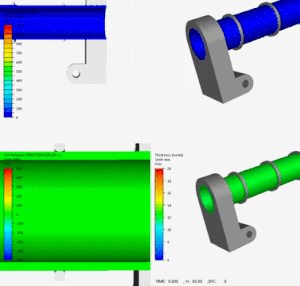

Thickness analysis during the bending process of a tube

Competitive features of fORGE® for bending processes

- The possibility to consider a local source of heat representing heating via induction

- Taking the behavior of the steel fully into account by considering:

- the metallurgical change during heating (austenitization)

- phase changes during cooling

- the elastic visco-plastic behavior of the steel according to the local metallurgy changing during the process

- the changes in the thermophysical data vary with the temperature and the local metallurgy

- the deformation generated by the phase changes during rapid cooling or heating

- The precise description of the kinematics of the tooling

Simulation of bending a tube with local heating via induction

The example above made with FORGE® software presents a complex bending operation of a thick tube. The steel tube is heated locally via induction in order to facilitate its deformation. During heating, metallurgical changes occur. The calculation makes it possible to estimate the efforts required for this process and to predict the local thicknesses of the tube after bending.