Predict cracks apparition and propagation

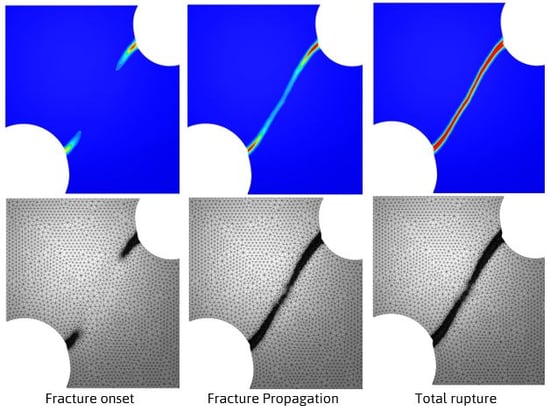

With each generation of our FORGE® and COLDFORM® solutions, newer methodologies are being developed to improve the modeling of damage-to-fracture transition problems which are at the core of many forming application such as trimming and piercing. As well as to improve process design in which the target is to avoid the apparition of cracks, making it necessary to accurately predict the onset and propagation of ductile fracture.

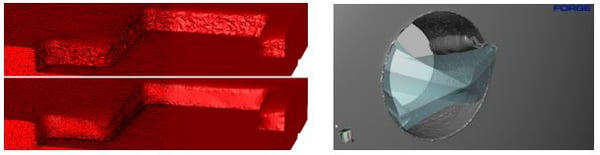

In FORGE® and COLDFORM® a novel strategy consisting in combining the “kill-element” method with surface smoothing operations enables to greatly improve the quality of the final parts.

Current state-of-the-art: Robust damage modeling with kill-element and smoothing techniques

Current state-of-the-art: Robust damage modeling with kill-element and smoothing techniques

In parallel, a research project was launched to study novel methodologies to pave the path for improved simulation of such processes.

Towards a uniform non-local and generic strategy for mesh management linked to damage & fracture

A doctoral student of the CEMEF (material forming center) share his time with Transvalor to conduct a thesis which will allow us to improve the damage-to-fracture transition model.

Subject: 3D numerical modeling of ductile fracture

Objectives:

- Introduce a non-local and generic framework for modeling of damage modes

- Develop an automatic mesh management based on this new framework enabling introduction of fracture surfaces without the typical loss-of-volume issue linked with the kill-element technique.

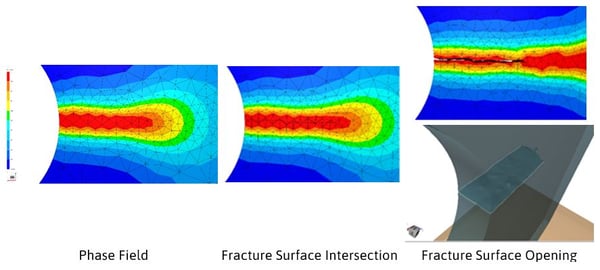

The first phase of the project has evolved in very positive manner by introducing the Phase-field (P.F.) concept as a generic mean of describing damage-to-fracture. By introducing a virtual field that describes in a continuum way the localization of damaged material (P.F. = 0 if no accumulated damage, P.F. = 1 for fully damaged material) and taking advantage of automatic remeshing strategies it is now possible to simulate the damage onset, propagation and total rupture with minimal computational cost: the mesh is automatically refined following the Phase-field.

The next phase of the project will consist in using these results as the basis for introducing the actual fracture surface progressively. A first glimpse to what’s to come:

More details about this project?