We are pleased to announce the release of THERCAST® NxT 2.0 version, which has been improved following your comments and recommendations. New functionalities, improvement of existing functionalities and new graphical interface, discover the essentials of THERCAST® NxT 2.0 in the following points.

A new powerful and intuitive graphical interface

Our GUI team has developed a new multilingual and business-oriented graphical interface, bringing you a simplified and personalized user experience.

- Manipulation on multiple objects (rotation, trimming, motion, etc.).

Benefits: Simpler analysis.

- Improvement of centered rotation for tilt casting.

Benefits: Simulation closer from reality, easier and more accurate process analysis .

- Integration of 'Custom Actions' applicable in a single clic.

Benefts: Customizing of the results display for a more accurate analysis.

- Preview of the cycling thanks to the visualization of the active regulation zones within the kinematics preview.

Benefits: Optimization of the shake-out time for the paramaters of the casting machine.

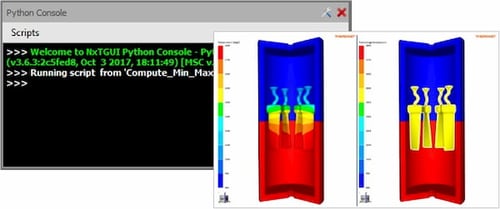

- Integration of the Python console for post-process of scalar results.

Benefits: Access to a simple user language in analysis mode.

New or significantly improved functionalities

- Improvement of the heat transfer radiation model. Read more

Benefits: Improvement of the precision of the results of this function with a big reduction in CPU times and more intuitive interface.

- Integration of an inclusion manager with dedicated area for data setup.

Benefits: Easier data setup and more accurate analysis.

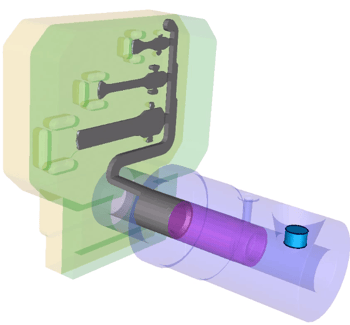

- Integration of an inlet manager with definition of parameters for geometry, filling, mesh, dynamic or not, submerged or not, etc.

Benefits: Advanced parametrization of metal injection without orientation, trajectory or geometry constraints.

Example of inlet on a high pressure die casting application.

- New global slice computation model for continuous casting. Read more

Benefits: Significant reduction in calculation times.

- Integration of filters in foundry casting with setting of the shape of the filter and the control model for pressure/velocity.

Benefits: More realistic simulation of the fluid flow control and of the metal cleaning through the filter.

Simulation of filling performed at the same time without filter (left) and with filter (right)

- New mold/part meshing tool to create a mold mesh from a part and vice versa.

Benefits: Automatic definition of computation areas.

- New specific remeshing tool to merge the meshes of several objects.

Benefits: Make it possible to join components with the same characteristics into a single object.

- Consideration of temperature-dependent exothermic reaction for powder.

Benefits: Simulation closer to reality with taking into account of temperature.

- Temperature driven cycling.

Benefits: Simulation closer to reality with taking into account of temperature.

Access to high value-added tools

- Significant improvement of the automatic remeshing during computation (FORCE).

Benefits: Better precision of the automatic remeshing, strong reduction of computation times, reduction of data setup times.

Automatic remeshing on aluminum foundry casting.

- Access to JMatPro TTT database files (TTT diagram, rheological behavior, austenitization, etc.).

Benefits: Extended materials database, better analysis of metallurgical phenomena.

- Access to user scripts: for the experts, creation of 'user routines'.

Benefits: From the fields already available in THERCAST®, creation of its own routines in the results given by THERCAST®.

- New tutorials (directional solidification casting, centrifugal casting, tilt casting...).