The microstructural state of a metallic material plays a major role in its properties of use and its mechanical behavior during shaping. It is now necessary to master these changes throughout industrial processes to meet demanding specifications and respond effectively to new markets.

DIGIMU® 3.0 FOR THE PHYSICAL MODELING OF POLYCRYSTALLINE EVOLUTIONS DURING THERMOMECHANICAL PROCESSES FOR SHAPING METALLIC MATERIALS

The simulation software for shaping materials available to industrialists allows the use of metallurgical models mainly based on phenomenological equations or medium-field models. However, the range of validity of these models associated with a set of parameters is often limited to a material and a process. Constantly re-identifying these parameters by experimental studies means prohibitive costs.

Over the last twenty years, full-field academic modeling solutions have emerged. These methods involve a direct modeling of the evolution of a polycrystal on a representative elementary volume at the mesoscopic scale. The modeling of the physical mechanisms at work making these simulations more generic.

Since 2016, Transvalor has been offering the first commercial software for modeling full-field microstructure evolutions.

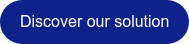

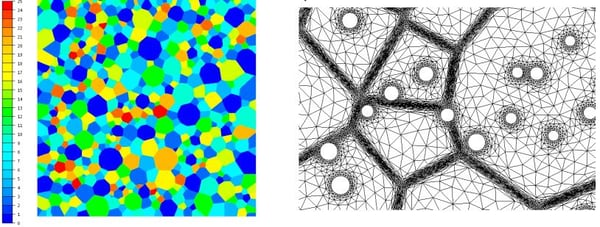

Coming from the academic work of the CEMEF, DIGIMU®V3.0 released in 2018 allows to model generically in 2D, by coupling phenomenological approach for the deformation and Eulerian modeling of the interfaces, the migration of grain boundaries with or without particles of second phases , the deformation of the polycrystal, hardening and restoration, static and dynamic recrystallization, as well as the couplings between these physical phenomena.

Download the article (in french)