Transvalor in collaboration with the University of Strathclyde’s Advanced Forming Research Centre (AFRC) has organized the Tech Days dedicated to the manufacturing industry. This new formula was adapted to the current situation: these Tech Days were given during two days of free webinars and open to everyone.

Webinars on process simulation

Wednesday June 17th, 2020

10:30-11:30 : Exploring process simulation for hot & cold metal forming applications

- Dr. Nadine EL KOSSEIFI (FORGE® & COLDFORM® Product Manager)

- Laëtitia PÉGIÉ (Head of Customer Service Department, Transvalor)

Overview: This webinar aims at presenting the latest developments made around FORGE® and COLDFORM® software. A special focus will be given on enhancements adressing the ease of use and the overall user experience. A selection of recent customer applications will highlight the benefits of simulation in the metal forming industry.

Agenda: Review of FORGE® & COLDFORM® range of capabilities • Latest enhancements to improve the user experience • Example of recent industrial applications (isothermal forging, electrical upsetting, fastening solutions...) • Forthcoming axis of development, product roadmap • Q&A and Discussions

14:00-15:00 : Novelties in simulation of heat treatment processes

- Dr. José ALVES (Senior Scientific Developer, Transvalor)

Overview: This webinar aims at presenting the advances implemented into FORGE® and SIMHEAT® software regarding simulation of heat treatment processes. A special focus will be given on recent developments to model the induction phenomenon and its application to induction hardening. Moreover, key engineering aspects for heat treatment of aluminium alloys will be presented aiming at predicting final mechanical properties of forged or cast components.

Agenda: New developements upon induction-based processes (stationary fields, self-induction, Lorentz forces...) • Heat treatment of aluminium alloys (quenching and artificial ageing, QFA and Shercliff-Ashby models to predict final mechanical properties...) • Q&A and Discussions

Thursday June 18th, 2020

10:30-11:30 : Mean field and full field microstructural modelling for hot forging on example of Inconel 718

- Dr. Olga BYLYA (Research Fellow, Advanced Forming Research Centre)

- Dr. Pascal DE MICHELI (DIGIMU® Project Manager, Transvalor)

Overview: This webinar aims to discuss challenges and advances related to microstructural modelling for hot forging. Mean field (JMAK type models) and full field approaches with DIGIMU® software will be presented on different problems related to microstructural behavior of Inconel 718 during hot forging: grain growth, dynamic recrystallization, abnormal grain growth. This webinar will be focused on parameters identification and validation of the results on labor tests and industrial trials.

Agenda: Main challenges in microstructural modelling for industrial hot forging • Applicability of mean field models: results of benchmarking • Ways of improvement, potential and challenges of multiscale modelling • Parameters identification and validation of different models • Microstructural simulation solutions at Transvalor • Overview of DIGIMU 4.0 release • Identification and validation of Inconel material model at IBF (RWTH Aachen) • Simulations of AFRC benchmarks • Q&A and Discussions

14:00-15:00 : Discovering THERCAST® NxT 2.0 for solidification and metal casting simulation

- Dr. Olivier JAOUEN (THERCAST® Technical Product Manager, Transvalor)

Overview: This webinar aims at presenting the latest release THERCAST® NxT 2.0 software dedicated to metal casting (non-permanent mold casting, die casting, investment casting, ingot casting, continuous casting...). Participants will discover a full range of new enhancements that significantly increase the ability to model the complexity of the physics that occurs filling and solidification. A special focus will be given as well on the overall user experience through practical industrial examples.

Agenda: Review of THERCAST® NxT 2.0 new features (self-radiation, inclusions manager, filters, adaptive remeshing...) • Enhancements to improve the user experience • Examples of industrial applications (low and high-pressure die casting) • Forthcoming axis of development, product roadmap • Q&A and Discussions

15:30-16:30 : Transvalor's vision to serve the manufacturing industry

- Oliver SCHWESINGER (Sales Manager, Transvalor)

Overview:

This webinar ends the series of 5. As a matter of conclusion, it aims at giving detailed insights about Transvalor's vision for the manufacturing industry and understand the major axis of development that drive our strategy. We are at a crossroads regarding simulation today and profound evolutions of our software are going to be introduced to better serve your business. Last but not least, a Live Q&A session is organized where all participants will have the opportunity to ask questions and communicate with the speakers of the preceding webinars.

Agenda: Transvalor global value proposition for the manufacturing industry • Strategic axis of development and business model evolution • Simulating the complete manufacturing chain, Interoperability for integrated process/product design simulation • Trends for Cloud Computing Services in SaaS mode • Live Q&A session with our panel of speakers: questions and comments about any topics related to the preceding webinars

Additional informations:

- The following webinars were free but registration was required to participate.

- You could register to one or more webinars.

- Webinars were scheduled at CEST (Paris Time).

- Presentations were hold in English only. Tech Days in French and in German are held later.

Keep up-to-date on forging and foundry casting simulation

The webinars helped you to understand how to meet the main challenges of the manufacturing industry with process simulation: cost reduction, quality improvement, innovation, etc.

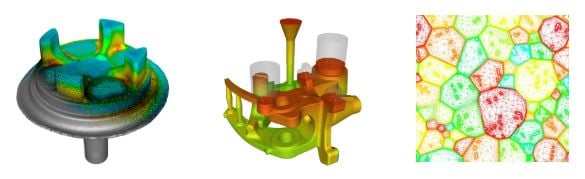

More specifically, the Tech Days tackled themes related to the forging and foundry processes, respectively honored by our simulation software FORGE® (hot/warm/cold forging), COLDFORM® (cold forming), SIMHEAT® (heat treatment), THERCAST® (casting), and DIGIMU® (microstructural evolution).

These webinars were intended for engineering managers, innovation managers, quality managers, metallurgist, manufacturing engineers, forging & tooling designers, casting & mold designers, process simulation engineers, research fellows, academics, PhD or MSc students.

In collaboration with the University of Strathclyde’s Advanced Forming Research Centre (AFRC)

These Tech Days were organised with support from the University of Strathclyde’s Advanced Forming Research Centre (AFRC) near Glasgow, UK, where Transvalor is now a Tier One Partner.

These Tech Days were organised with support from the University of Strathclyde’s Advanced Forming Research Centre (AFRC) near Glasgow, UK, where Transvalor is now a Tier One Partner.

Together we will work on joint projects focusing on materials and processes within its new FutureForge facility.

Opening in early 2021, FutureForge aims to transform the global forging sector by exploring less energy intensive methods of forging, also using digital technologies to accelerate the development of forged products by eliminating the costly trial and error traditionally associated with the forging process.

Dr Olga Bylya (Research Fellow at the AFRC) held a joint presentation with Pascal De Micheli (DIGIMU® Project Manager) on simulation of microstructural evolution.