Performance is an important advantage of THERCAST®.

Performance-optimized architecture

THERCAST® is optimized for very fast vector and matrix calculations, and has been designed to exploit very fast transfers between processors and memory.

Parallel processing

THERCAST® also includes a powerful parallel processing capability, allowing it to benefit from the power of unlimited numbers of core processors. Parallelism is based on the SPMD (single process, multiple data) technique, and it means that increases in performance, and reductions in simulation run time, substantially improve as additional processors are applied.

Accuracy

The performance and scalability of THERCAST® mean that your casting process can be simulated with larger numbers of smaller physical "elements," providing much greater process insights and much better accuracy – particularly near boundaries in the casting process or parts being cast.

More simulations

High performance allows simulations to be run more rapidly. This empowers you to run greater numbers of simulations, in order to examine the impacts and interrelationships of various parameters in your process.

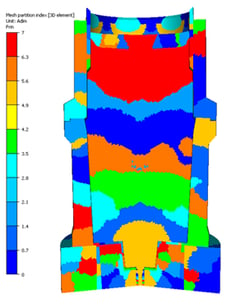

This image shows of a THERCAST® ingot casting simulation running on eight processor cores. It has been color-coded to show how different zones of the metal and mold are being simulated by different processors in parallel, providing dramatic increases in performance. This allows more simulations to be run, simulations to be run with smaller cell sizes for greater accuracy, or both.

This image shows of a THERCAST® ingot casting simulation running on eight processor cores. It has been color-coded to show how different zones of the metal and mold are being simulated by different processors in parallel, providing dramatic increases in performance. This allows more simulations to be run, simulations to be run with smaller cell sizes for greater accuracy, or both.

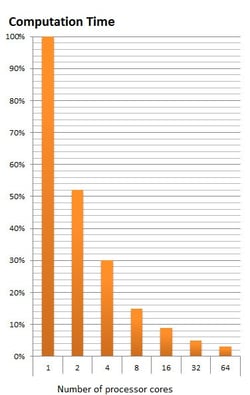

THERCAST® can operate on theoretically unlimited numbers of processor cores in parallel, providing substantial decreases in the time required to run simulations.

THERCAST® can operate on theoretically unlimited numbers of processor cores in parallel, providing substantial decreases in the time required to run simulations.