February 25th, 2021 - 02:30-03:15 PM CET (Paris Time)

Speakers: Nadine EL KOSSEIFI & Olivier JAOUEN, Marketing & Technical Product Managers

Metal-making companies are facing multiple challenges among which is the development of efficient technologies to supply specialized products and to access new growing markets.

Metal-making companies are facing multiple challenges among which is the development of efficient technologies to supply specialized products and to access new growing markets.

In this context, Transvalor’s software solutions for metal casting, open die forging and hot rolling are perfectly designed for industrials who wish to guarantee products of high quality.

Starting from continuous casting or ingot casting and followed by hot metal deformation processes, Transvalor provides a unique ‘End-to-End Solution’ to improve competitiveness and gain responsiveness in ever-changing markets. Whatever the manufacturing route is, it allows a quick and accurate analysis of the casting/forging/rolling processes.

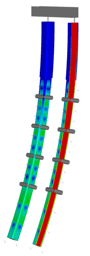

- This webinar will first introduce THERCAST® software for continuous casting applications including the steps to define the caster and the impact of process parameters (soft reduction or pinch rolls) on the final cast product. The new ‘global slice computation’ feature will be presented live with details on the benefits regarding computation time.

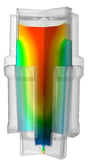

Second, a focus will be given on ingot casting. More precisely, the ability to anticipate defects (air gaps, shrinkage, porosities…) and to model metallurgical evolutions will be detailed.

Second, a focus will be given on ingot casting. More precisely, the ability to anticipate defects (air gaps, shrinkage, porosities…) and to model metallurgical evolutions will be detailed.- Third, this webinar will highlight all advantages of the unique software interoperability existing between THERCAST® and FORGE® to simulate the complete manufacturing process chain, thanks to the native interconnection between the two software.

Two cases will be presented:

- #1: a typical continuous casting example with a subsequent rolling process

- #2: analysis and comparison of forging or blooming manufacturing routes for austenitic stainless-steel bars (with courtesy of Tubacex - Spain)

Contact us for more details

Public: Engineering managers, Innovation managers, Quality managers, Metallurgists, Manufacturing engineers, Casting, Forging & Tooling designers, Process simulation engineers, Research fellows, Academics, PhD or MSc students.

Keywords: continuous casting, ingot casting, forging, manufacturing process, metal industry, steel making, metal forming, casting defects, forgign defects, numerical simulation, material science, mechanical engineering.