April 15th, 2021 - 02:30-03:15 PM CET (Paris Time)

Speakers: Aurore ULLY & Olivier JAOUEN, THERCAST® Product Managers

High Pressure Die Casting (HPDC) and Low Pressure Die Casting (LPDC) processes are widely used in the automotive industry as they enable the molding of precision parts with complex geometry such as engine housings or clutch housings.

In order to obtain zero-defect parts, THERCAST® software simulates each of these die casting technologies, allowing a complete and accurate analysis of your process, which shortens the prototyping phase.

In LPDC, the process consists in filling a permanent mold (shell) using low pressure that allows the metal to rise vertically and fill gradually the cavity.

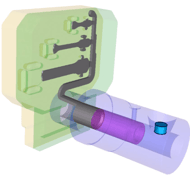

The HPDC process takes place in three phases:

- The first brings the metal to the casting die at low speed.

- The second fills the cavity at high speed.

- The last phase is a very high compression phase which makes it possible to fill the shrinkage of the metal during solidification and to strongly compress the porosities (blowholes, shrinkage) in the part.

In this webinar, we will show how THERCAST® can simulate all of these aspects and help you understand the impact of process parameters on the manufacturing of your HPDC or LPDC parts.

After a short introduction to HPDC and LPDC processes and the associated risks of defects, we will use simulation examples of a crankcase and a chassis part to show you how to set up your data for the HPDC or LPDC calculation.

Then, we will show you how to optimize each phase of your process and obtain a complete analysis to anticipate defects and improve your process.

Public: Engineering managers, Innovation managers, Quality managers, Metallurgists, Manufacturing engineers, Casting & Tooling designers, Process simulation engineers, Research fellows, Academics, PhD or MSc students.

Keywords: Foundry casting, High Pressure Die Casting (HPDC), Low Pressure Die Casting (LPDC), manufacturing process, automotive, defects, shrinkage, costs, quality, simulation, modeling, mechanical engineering

THERCAST® allows to quickly and accurately analyze your manufacturing process, from the initial casting to the end of solidification.