Brochures, case studies, videos… Discover and download our documents to find out more about Transvalor, our solutions and the world of material forming.

.png)

.png)

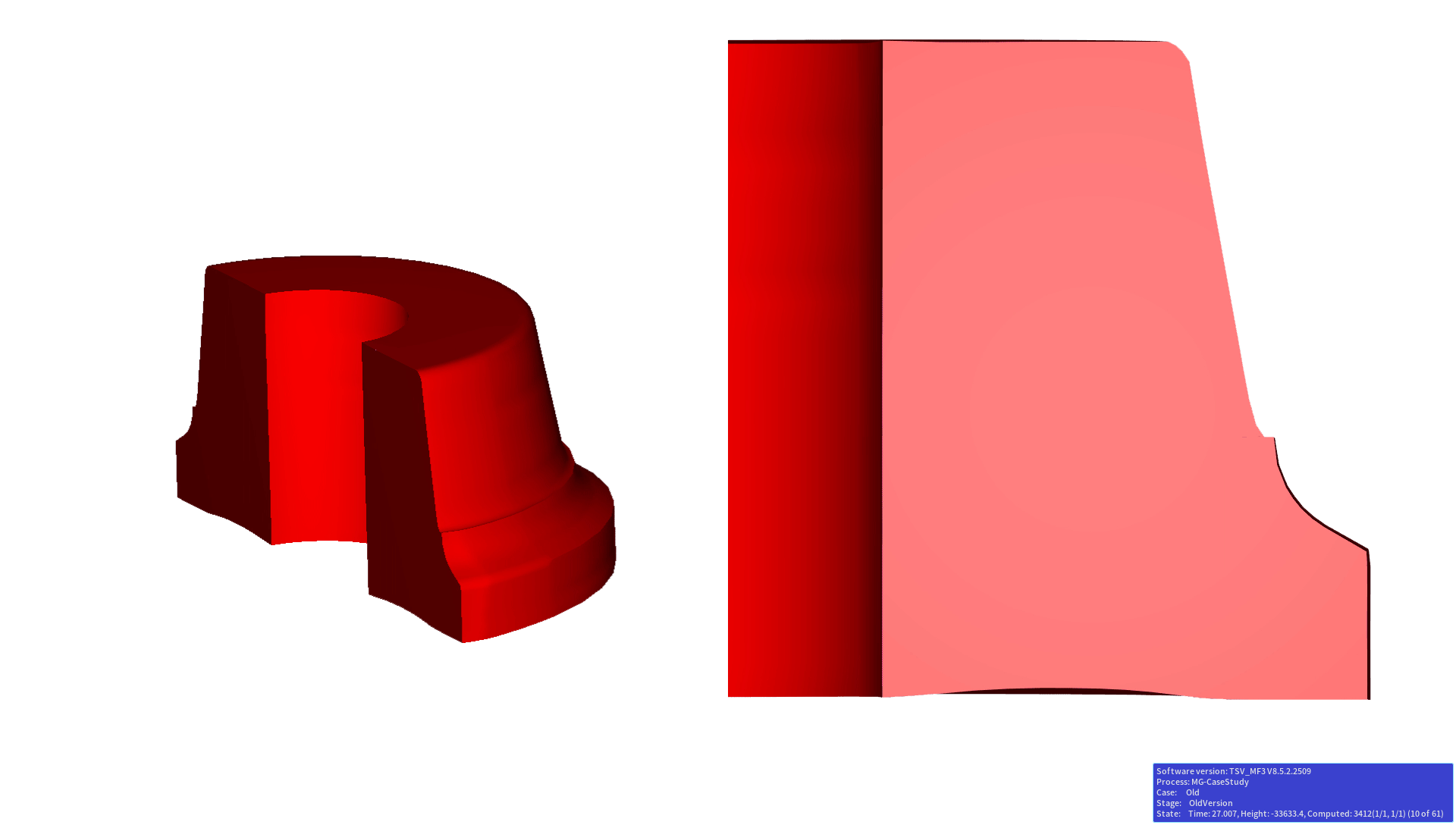

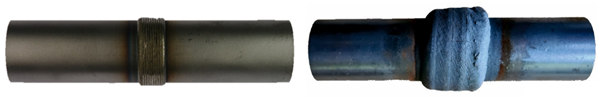

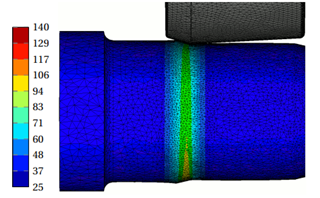

World leader in software for simulation of material forming processes.