NTN-SNR Roulements, world leader for bearings

NTN-SNR Roulements, part of NTN Corporation, is based in Annecy (France), world leader for bearings, transmission joints, linear modules, distribution rollers, suspension parts. Its activity is primarily automobile-oriented, and other sectors in industry such as aeronautics, rail, and the farming and mining sectors.

NTN-SNR Roulements, part of NTN Corporation, is based in Annecy (France), world leader for bearings, transmission joints, linear modules, distribution rollers, suspension parts. Its activity is primarily automobile-oriented, and other sectors in industry such as aeronautics, rail, and the farming and mining sectors.

Challenge: validate the induction hardening simulation process

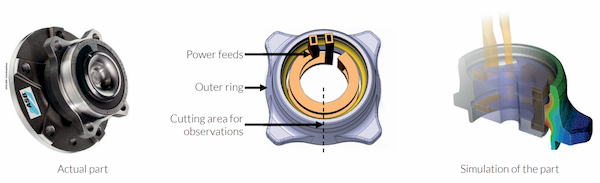

NTN-SNR uses the FORGE® software to simulate the induction hardening process used in manufacturing bearing rings. This treatment is applied on mechanical components in order to create a local structural hardening over a precise depth while still minimizing geometrical distortions and residual stresses. For bearing rings, this makes it possible to obtain a high hardness on the ball-raceway contacts while maintaining sufficient ductility elsewhere.

This process is complex because it requires a coupling between the electromagnetic, thermomechanical and metallurgical phenomena. Numerical simulation is commonly used in the initial design phase of the inductor and of the quenching system.

The difficulty resides in finding the ideal operating point for the generator and in predicting the metallurgical properties of the quenched part. Thus, by conducting this study, NTN-SNR wanted to understand:

- the setpoints to be applied to the generator such as the intensity of the current, the power and the frequency

- the impact of multi-physical couplings on the change in temperature, the residual stresses, distortions and metallurgical transformations that are at work during the process.

Solution: consider the characteristics of the current generator

To digitally simulate the behavior of the generator, FORGE® incorporates an iterative algorithm that accurately calculates the frequency and the intensity in order to maintain a constant power equal to the setpoint. Simulating the induction heating is carried out using two solvers of which the first one solves the electromagnetic equations and calculates the power density generated by the induced currents, while the second solves in a coupled manner the thermal-mechanical-metallurgical equations. The two solvers are coupled in order to update the electromagnetic properties of the part.

The solution chosen to report on the behavior of the generator allows:

- to automatically deduce the frequency and the intensity of the current to operate at the state of resonance

- to consider the influence of the Curie transformation point with a dependency on the magnetic and electrical properties according to the temperature and the magnetic field

By integrating the generator into the simulation, NTN-SNR was also able to optimize its parameters and determine the current and the frequency of the inductor that is optimal to carry out for the production phase. A good agreement is found between the electrical values recorded (voltage, intensity, frequency) and the simulated behavior of the generator.

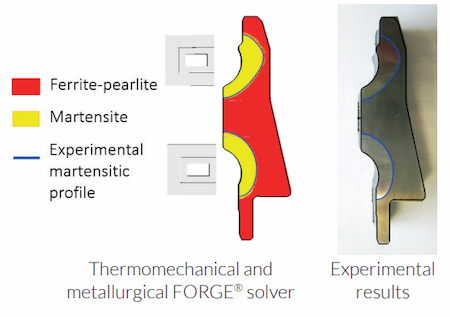

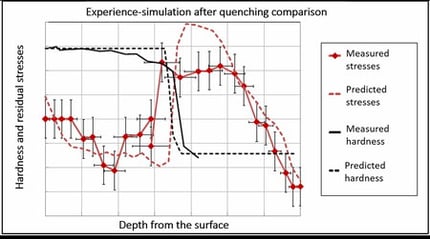

The solution makes it possible to highlight a strong correlation between the simulation and the experimental measurements on:

- the quenched depth and the defined shape

- the deformation of the ring to the heat treatment

- the hardness and the stresses

- the microstructure and the martensitic profile

Distribution map of the longitudinal axial stresses

«The work carried out with the support from Transvalor made it possible in the FORGE® software to implement a new description of the behavior of the power generator. Integrating the operating point of the generator into the simulation makes it possible to obtain a single and full solution for developing the entire induction hardening process. »

- Victor Lejay, Process Development Engineer at NTN-SNR Roulements

Benefits: simulate the process as a whole

With FORGE®, NTN-SNR benefits from a fast and predictive solution, which makes it possible to simulate the process as a whole from the generator to quenching.

The solution was validated experimentally on C56 steel bearing rings which thus allows NTNSNR to:

- Identify right from the simulation stage the optimum position of the operating point of the generator

- Integrate the behavior of the actual generator into the simulation without having to perform a complex calculation to switch from the power setpoint to the intensity of the current

- Predict the microstructural change in the bearing rings, in particular the shape and the depth of the quenched area

- Correlate the measurements of distorsions and residual stresses after quenching

- Control the out-of-round phenomena by checking the distorsions after quenching

All of these elements have allowed NTN-SNR to optimize the settings of the generator in order to propose a solution that takes account of all of the steps of induction hardening.

« The FORGE® solution is predictive because the parameters of the generator are used as they are as input data in the simulation for predicting the metallurgical properties of the part »