Simulation of sheet metal forming with FORGE®

Sheet metal forming is used for manufacturing thin products. The process can be carried out as a cold or a hot forming process (Hot Press Forming, HPF).

FORGE® simulates both types of sheet metal forming operations in order to optimize process parameters and to ensure the parts’ quality.

predictive simulation

FORGE® allows accurate prediction of:

- Final shape with the prediction of final thickness

- Defects like striction

- Residual stresses

- Press loads including loads to apply on the blank holders

- Metallurgic changes in the case of Hot Press Forming

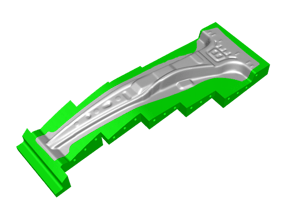

Flow limit diagram with FORGE®

Flow limit diagram with FORGE®

features oF FORGE® for sheet metal forming

- Dedicated meshing technology for thin products allowing multiple elements in the thickness without impacting CPU time

- Genuine elasto-plastic model for cold operations for accurate elastic spring back and residual stresses

- Anisotropic models and complex hardening models (kinematic hardening)

- For HPF, embedded heat treatment models to accurately predict metallurgic phase transformation and martensite production

- Accurate temperature prediction thanks to coupled part-dies analysis

- With a unique software, multiple operations can be achieved: forming operations as well as subsequent blanking operations are accurately and easily analyzed

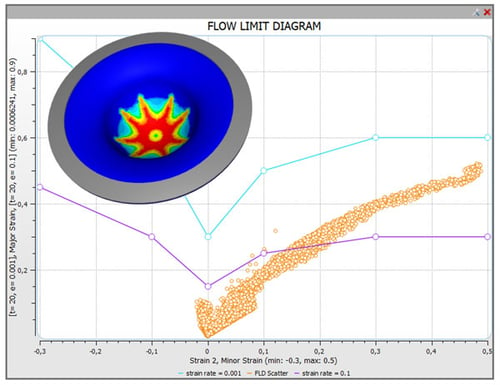

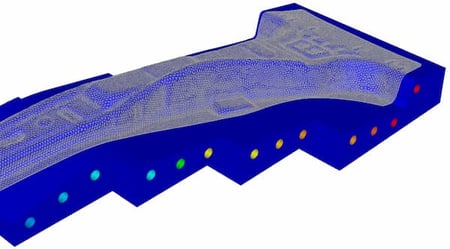

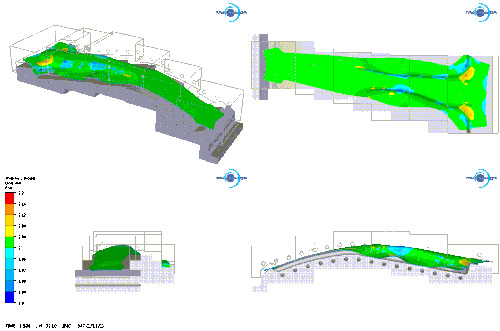

Case study: sheet metal forming of a car B-pillar

.jpg?width=400&name=FORGE_emboutissage%20(2).jpg)

The example presented here corresponds to the hot forming of a B-pillar in a car body. Following the stamping operation, the part formed is cooled between the two dies which makes it possible to check its microstructure and its final shape. The FORGE® software can be used in this type of configuration and considering the microstructural changes.

Thickness evolution

Temperature evolution