NEW TOOLS FOR MANAGING YOUR SIMULATION PROJECTS

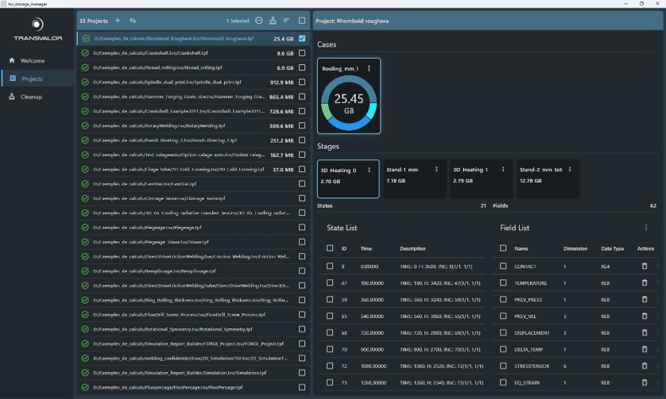

- Simulation Project Archiving Tool: Storage Manager.

Simulation results are often very large and take up significant space on backup drives. This tool allows you to compress results and remove unnecessary data for final project archiving. Once calculations are complete, the project(s) can be loaded into this utility to sort/remove non-essential results and compress the data.

Benefits: Significant disk space savings without compromising result consistency.

- Automatic Procedure for Updating Simulation Projects.

Benefits: Automatic availability of new options in Templates.

- New Calculation Launch Procedure.

The process for submitting and running calculations has been completely redesigned for this version. New functions have been introduced via the Python API to ensure greater simplicity, flexibility, and control.

SOLVER IMPROVEMENTS

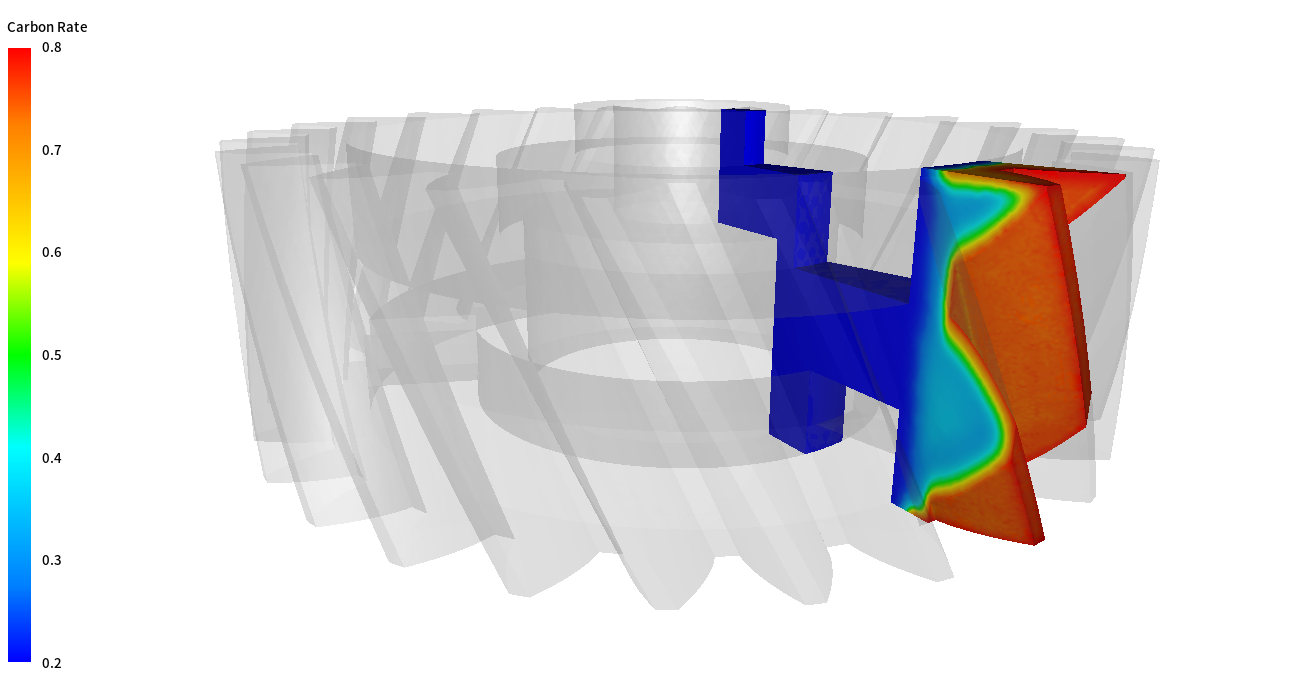

- Cyclic Symmetries for Heat Treatments.

Cyclic symmetries are now supported for heating, cooling/quenching, and thermochemical treatments such as carburizing, nitriding, and carbonitriding. For helical parts, only one tooth or section of the part can be modeled.

- Extension of Stationary Cold Rolling.

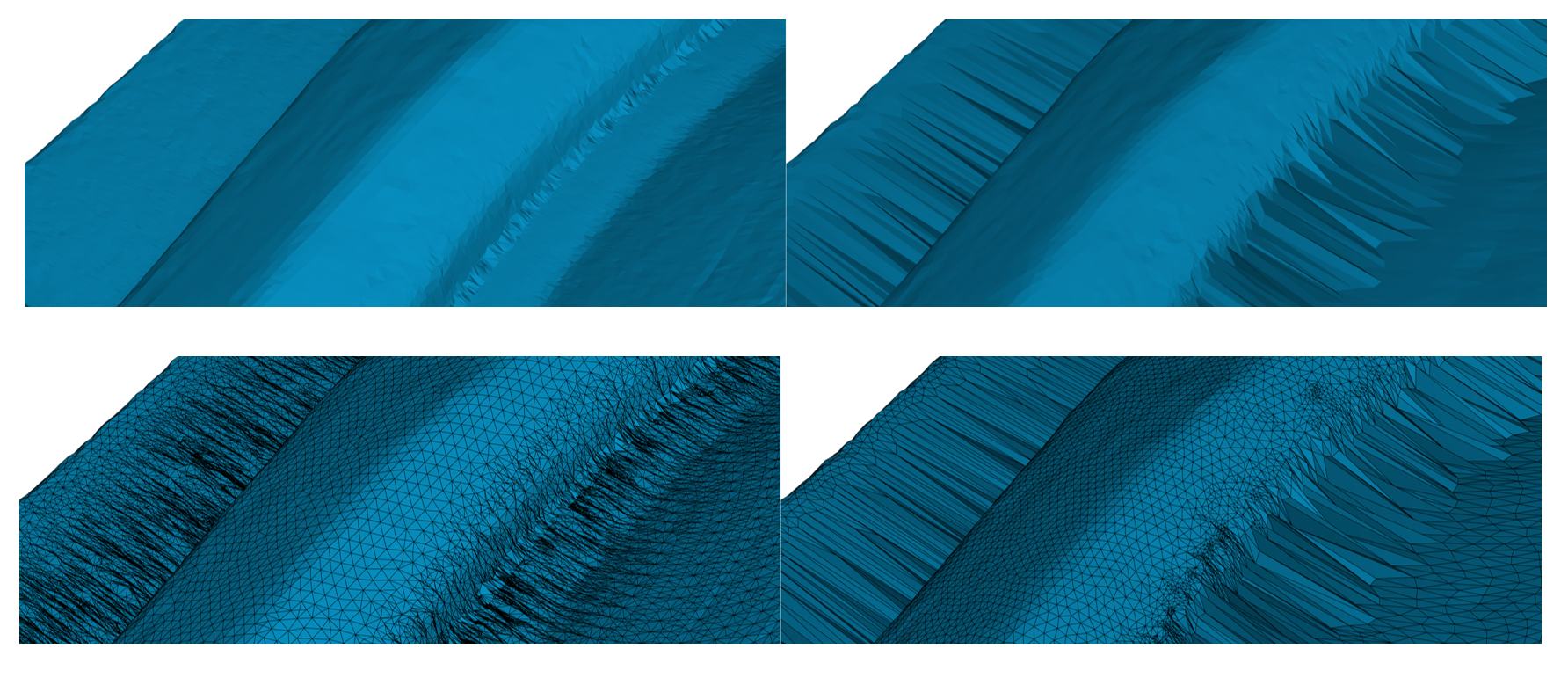

- Improved Subsurface Mark Remeshing.

Benefits: More robust detection of forging defects (folds, suction effects).

On the left, FORGE® NxT 4.1, and on the right, FORGE® NxT 4.0.

NEW FEATURES FOR DATA SETUP AND RESULT ANALYSIS

- Automation of Setups and Result Analysis.

Benefits: Increased efficiency in daily tasks, time savings, and unlocking new possibilities for result analysis.

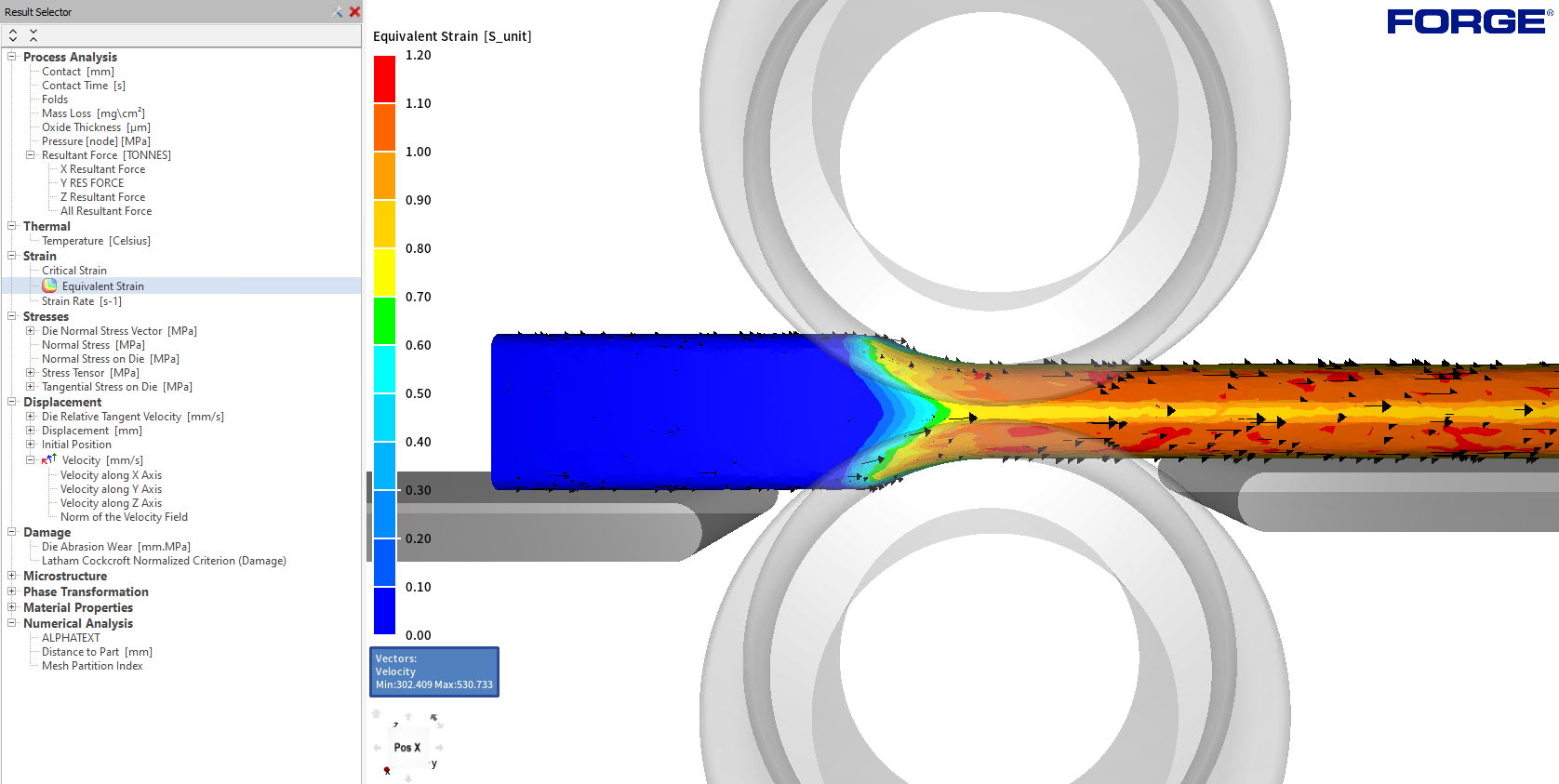

- Improved Result Visualization.

The display of calculation results in the "Result Selector" window has been enhanced. Results are now categorized, accessible within the same window, and customizable (names, groups, units).