Understanding and Analyzing with Rheology Software

PU foams are widely used in several sectors including automotive, household appliances and leisure. REM3D® software is used to finely simulate the injection and foam molding process and thus verify the influence of the application conditions.

This article first introduces the contribution of simulation for injection processes and then details the innovative characteristics of the software developed to meet the requirements of the process. Since material data are essential, we describe a methodology for characterizing PU foams. Based on experimentally measured physical and thermo-kinetic properties, a numerical method of automatic optimization makes it possible to obtain the parameters of the material sheet. Operated by the simulation tool, these data conform to real formulations and increase the quality of the results.

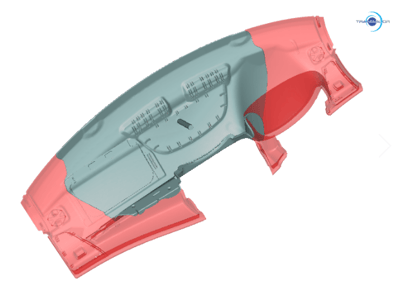

PU foam expansion during the filling of a dashboard

PU foam expansion during the filling of a dashboard

In conclusion, several examples illustrate the contribution of simulation on industrial parts and show the extent of the results among which the density of foam in each zone of the room; an essential indicator for estimating the quality of parts and their performance.