In pursuit of quality and efficiency, the industry has embraced new digital and simulation tools to meet its demands. The industry 4.0 factory has piqued growing interest in the foam industry, enabling precise definition of process parameters, anticipation of defects, and optimization of tooling utilization. The methodology developed by TRANSVALOR, based on FOAMAT® Systems and the optimization tool TRANSFOAM® by TRANSVALOR, addresses this demand by offering personalized characterization, thus enabling sustainable and efficient manufacturing through digital simulation.

The Rise of Industry 4.0 and its Impact on Foam Manufacturing

In an industrial world that demands ever-greater quality, cost reduction, and faster development times, manufacturers must adopt new tools to achieve their objectives. Industry 4.0 aims to digitize the manufacturing sector, particularly in the foam industry. Digital tools allow for precise definition of process parameters, anticipation of defect issues, and interaction with tooling. Given the high costs and production times of tooling, predicting an optimized configuration through shaping simulation software has become essential.

Polyurethane Foam: Versatility and Applications

Polyurethane foam finds a wide variety of applications, whether for sound, vibration, or thermal insulation, making it present in various sectors such as automotive or refrigeration. The targeted geometries and material quantities vary considerably depending on the applications, ranging from a few cm3 to several dm3. To meet these challenges, digital simulation relies on process data (tooling, materials, shapes, etc.) as well as material behavior laws that precisely define the flow of the product in its liquid state, its behavior during solidification, and its expansion.

Polyurethane foam is obtained from a mixture of polyol and isocyanate, whose proportions greatly influence the foam's behavior and reactivity. Since mixing parameters significantly impact the final material behavior, it is essential to characterize foams in a personalized manner.

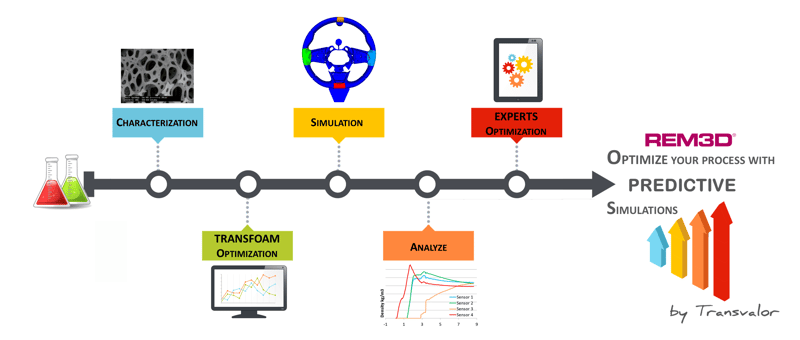

A complete process Analysis and Optimization via FOAMAT® and TRANSFOAM® to perform the most predictive REM3D simulation

This characterization method is based on an initial step, a FOAMAT® experiment. This consists of filling a cylinder of defined diameter with a specific mass of liquid mixture and then observing the foaming and filling process of the cylinder. FOAMAT® enables monitoring the temperature evolution and reaction kinetics during foaming.

Isocyanate & Polyol formulation characterization experiments with FOAMAT®

Parameters optimization with TRANSFOAM®

REM3D®: Powering Optimization and Precision

To input precise results into the REM3D® software, it is essential to identify the parameters of the selected behavior law. Transvalor provides an optimization engine, TRANSFOAM®, which ensures a good determination of the foam expansion parameters. This methodology allows verifying the relevance of the behavior law by simulating the test with the identified parameters. Once this test is successful, the simulation of the real case can begin.

Simulation of the process with REM3D®

With FOAMAT® Systems TRANSFORAM® and REM3D® simulation, you can now:

- Estimate the material density at any point in the volume of the part.

- Estimate filling speeds and consequently the filling time.

- Estimate the shot weight of the foam

- Optimize the position and quantity of vents, as well as potential air traps.