What is high-pressure die casting?

High-Pressure Die Casting (HPDC) is a process for the large-scale production of precision parts at relatively low costs because it can be easily automated.

In more detail, after pouring the metal into the chamber, this process is broken down into 3 phases:

- An initial low-speed phase in which the metal is pushed into the chamber up to the ingates.

- A second phase of high-speed injection into the mold cavity.

- Finally, a third phase in which the piston maintains constant pressure throughout the solidification period.

Unlike low-pressure die casting, the metal is not necessarily injected vertically through the bottom of the mold.

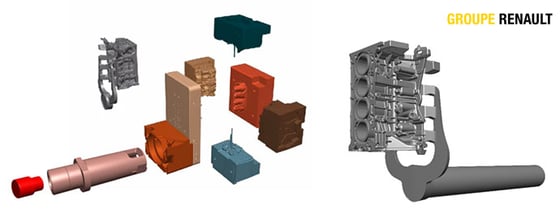

Modeling each part of the high-pressure die casting process for the manufacture of a casing: final part (gray), molds, cores, piston, stem, etc. Courtesy of Renault Group

Benefits of high-pressure die casting

This process is known for its high precision guaranteeing quality manufacturing for very fine or complex parts. Thus, the high-pressure die casting process is referred to as "near-net-shape manufacturing".

Often used to manufacture parts made of lightweight alloys such as aluminum, but also zinc (Zamak, etc.) and magnesium alloys, the speed of the process is particularly well-suited to automated large series production, ensuring consistency in the quality of the parts. It is therefore mainly found in the automotive industry for the manufacture of aluminum crankcases (engine, clutch, etc.). Other industries such as electronics, medical, sports, luxury goods and construction also apply high-pressure die casting to manufacture zinc alloy hydraulic components or magnesium alloy structural parts.

Often used to manufacture parts made of lightweight alloys such as aluminum, but also zinc (Zamak, etc.) and magnesium alloys, the speed of the process is particularly well-suited to automated large series production, ensuring consistency in the quality of the parts. It is therefore mainly found in the automotive industry for the manufacture of aluminum crankcases (engine, clutch, etc.). Other industries such as electronics, medical, sports, luxury goods and construction also apply high-pressure die casting to manufacture zinc alloy hydraulic components or magnesium alloy structural parts.

The manufactured parts, however, are often more porous than by sand casting or die casting due to the very high solidification rates. Moreover, defects are not always compensated by the action of the piston pressure in phase 3. These can, however, be anticipated with the help of numerical simulation.

Predictive simulation of high-pressure die casting

The THERCAST® software dedicated to casting processes, allows the precise and predictive analysis of the high-pressure die casting process, from filling to solidification:

- Configuration of all process parameters: mold component geometries, materials, operating temperatures, pressure graph, thermal exchange and coating zones, cooling channels, etc.

- Modeling all process phases: mold warm-up, chamber filling with a casting bucket, moving the piston, metal rising into the mold and holding, circulation of cooling fluids, ejection of the part

- Visualization of metal flow and integration of its impact

- Visualization of metal shrinkage during solidification

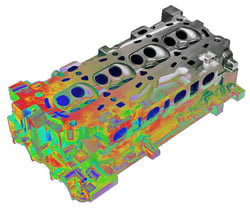

Metal front evolution during high-pressure die casting of a crankcase. Courtesy of Groupe Renault.

- Defect prediction: primary and secondary shrinkages, inclusions, hot tears, cracks, short runs and misruns, etc.

- Air bubble monitoring

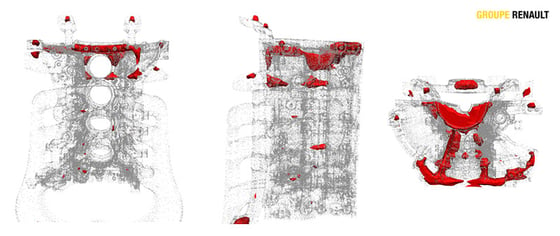

- Mold analysis: temperature and deformation, real kinematics of moving parts

- Metallurgical changes: distribution of liquid/solid phases, grain growth and orientation, micro and macro-segregation

- Cycle time optimization according to part design

- Ingate optimization

Part porosity detection

THERCAST® features for high-pressure die casting

- High-pressure die casting-specific simulation template

- Coupling of fluid mechanics and solid mechanics throughout the calculation

- Parallelized computation for faster execution

- Launch of a complete thermomechanical analysis for high accuracy of results

Coupled thermomechanical resolution in the part and in all mold components (including inserts and pins) to anticipate deformations

Coupled thermomechanical resolution in the part and in all mold components (including inserts and pins) to anticipate deformations- Feed system optimization for weight and yield gains

- Complete metallurgical analysis

- Materials database and dedicated creation space

- Configuration of TTT diagrams (time-temperature-transformation)

- THERCAST® results can be exported to other calculation or finite element software packages

- Perfect interoperability with SIMHEAT® software which simulates the heat treatment of post-foundry parts.

- Inclusion monitoring throughout the process. More information

- Perfect simulation of thermal cycling for a faithful consideration of its impact.

Key benefits of THERCAST®

THERCAST® has features to increase the precision of computational results and reduce the cost of manufacturing parts made by high-pressure die casting:

- "Filling and Solidification" can be simulated at any time with a single application: the "Fluid Mechanics" and "Solid Mechanics" calculations are fully integrated.

- THERCAST® incorporates scalable contact management to detect any detachment between the cast metal and the mold. As soon as the shrinkage appears, the software takes into account the influence of the air gaps and locally adapts the thermal exchange between the metal and the mold.

- Thermal and Mechanical resolution can be coupled and the associated calculations can be performed at the same time. THERCAST® can therefore model mold deformation according to part deformation and vice versa. Both phenomena occur simultaneously.

- The software can visualize the stresses applied by the metal to the pins, under the pressure exerted by the piston. It is thus possible to predict mold deformation and the potential impact on part geometry.

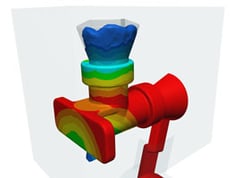

Von Mises stress on the mold and the pins

- The study of feed system optimization is used to precisely define the minimum amount of material needed to manufacture the desired part.

- Process input data can be configured to determine the mass of metal to be injected and thus limit losses. Reducing material losses saves valuable money across the manufacturing process.

- The ability to model thermal cycling and mold kinematics allows a faithful study of the high-pressure die casting process

- The actions on each object and the ability to manage the core ejection sequence contribute to a higher level of thermal flow precision.

Mold filling by high-pressure die casting for test piece manufacture