There are significant challenges to be faced in order to meet the CO2 emissions targets and combat climate change. We have to reinvent processes and products quickly, and new materials are of course part of it.

Transvalor helps you to acquire knowledge about new materials so that you stand in the first place in the competition for new products.

This is the reason why we have organized our first event dedicated to the simulation of microstructural evolution.

Why WAS IT IMPORTANT TO attend this event?

- To discover the possibilities given by our software suite to predict microstructural evolutions: from casting to forging and welding to fatigue analysis.

- To learn how Transvalor helps customers to characterize new material properties at the microstructural level.

- To meet our industrial and academic customers and see how they use our software and benefit from the simulation

- To discuss with Transvalor experts and see how the Transvalor solution covers the entire manufacturing chain. On top of the presentations there was a dedicated technical booth to exchange with our experts on how Transvalor can help overcome challenges.

WHAT WAS DISCUSSED DURING THE EVENT?

Transvalor showed to attendees the important place the prediction of the microstructure occupies in industry and research in order to define new materials and improve the quality of the products.

They discovered the latest state-of-the-art approaches to meet their microstructural challenges on steels, Ni-alloys, aluminum and other materials. They also learn more about grain growth, recrystallization and precipitation during forging and heat treatments.

- Design new materials and stand in the first place in the competition

- Reduce industrial risks related to the microstructure of materials

- Optimize processes and parts for their applications

- Understand and control the grain size evolution in parts

agenda

10h00 - 11h00 Registration

11h00 - 11h20 Transvalor's Journey to 2024 - Transvalor, Dr. Stéphane Heitz, Deputy CEO11h20 - 11h40 Why Microstructure Prediction? Experience with the Transvalor solution for the entire manufacturing process - Transvalor, Dr. Pascal de Micheli11h40 - 12h00 Why and how to take advantage of DIGIMU® simulations in an industrial and an academic context - Transvalor, Dr. Pascal de Micheli12h00 - 13h00 Lunch break13h00 - 13h35 Benefits of DIGIMU® of the simulation of industrial forging processes with new nickel superalloys at Aubert&Duval - Aubert & Duval, Dr. Jérôme Blaizot13h35 - 14h10 How microstructure simulation helps optimize the process of future designs at Safran Tech - Safran Tech, Dr. Chi-Toan Nguyen14h10 - 14h45 Recent innovations in microstructure modeling at CEMEF - CEMEF, Prof. Marc Bernacki14h45 - 15h45 Coffee break, networking, test the software15h45 - 16h20 Material identification and microstructural simulation of a Ni-alloy for a wide range of thermomechanical conditions - RWTH Aachen University IBF, Ing. Holger Brüggemann16h20 - 16h55 Microstructural simulations compared to experimental observations on Ni-alloys - National Manufacturing Institute Scotland, Dr. Olga Bylya16h55 - 17h30 Automatic thermomechanical tester for microstructural characterization - Mondragon University, Prof. Lander Galdos, Ing. Julen Agirre17h30 - 18h05 Integrating an in-house mean field model in FORGE® with DynamiX GUI - Fraunhofer IWM, Lukas Kertsch, Dr. Maksim Zapara19h30 - 22h00 Cozy get-together

08h30 - 09h05 Better understand and simulate aluminum continuous recrystallization with DIGIMU® - CEMEF, Prof. Marc Bernacki09h05 - 09h40 Modelling Polycrystalline Materials using Z-set software - examples of application - Transvalor, Dr. Nikolay Osipov09h40 - 10h15 Accurate prediction of Zirconium continuous recrystallization with DIGIMU® - Framatome, Ing. Victor Grand10h15 - 10h55 Coffee break, test the software10h55 - 11h30 Improvement of microstructure predictions by modelling precipitates evolution in DIGIMU® - Transvalor, Dr. Karen Alvarado11h30 - 12h05 Heat treatments and precipitation evolution predictions for aluminium in FORGE® - Transvalor, Dr. Pascal de Micheli, Development engineer12h05 - 12h40 DynamiX : a mean field grain size prediction model to link the modelling scales of DIGIMU® and FORGE® - Transvalor, Dr. Pascal de Micheli, Development engineer12h40 - 13h40 Lunch13h40 - 14h30 Networking, test the software and Farewell

Networking

Technical booth

Transvalor experts were available during the networking times in a dedicated area. Attendees were able to learn more about predicting the microstructure in the various forming processes. Our employees showed them how the Transvalor simulation solutions for forging, casting, etc. can give a competitive edge in production.

Cozy Get-Together

Personal networking is very important to us, which is why the event was designed in such a way that there is time for extensive exchanges during the conference and of course a cozy get-together on Wednesday evening.

Simulation solutions for microstructure evolution

Transvalor is involved in research projects for more than 10 years to develop solutions for simulating the microstructural evolutions of metals alloys.

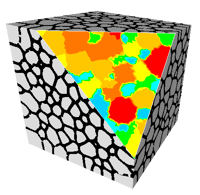

The purpose is to help industrials to predict microstructure changes, at the mesoscopic scale and on Representative Elementary Volumes (REVs), during metal forming processes.

For any inquiry concerning microstructure prediction in our solutions, let's get in touch.