Simulation of closed-die forging processes with FORGE®

In closed die forging, simulation is used for multiple purposes: to validate the forging sequence for quotation purposes, to solve shop-floor issues, to optimize the forging yield of existing components. FORGE® provides a fast and accurate insight into forged components.

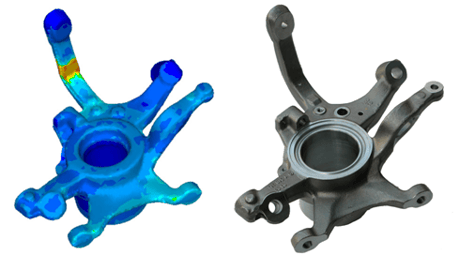

Steering knuckle (CDP BHARAT Forge GmbH)

predictive simulation with FORGE®

FORGE® allows the accurate prediction of:

- Final dimensions of the component

- Press load

- Defects like folds/laps, cracks, underfillings, piping defects, excess materials Read more

- Grain flow / Fibering

- Microstructural evolutions

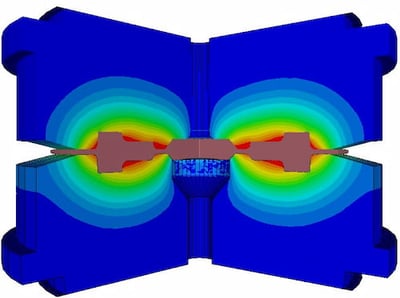

Filling analysis during the entire 3-stage sequence of a TA6V aerospace blade. Part of the blade in contact with the dies is represented in blue

competitive features FOR CLOSED-die forging

- Constitutive models for hot, warm and cold forging applicable for a wide range of materials. For cold forging, a genuine elasto-plastic model finely predicts the final dimensions of the part taking into consideration the elastic spring back (in particular for net-shape components).

- Microstructural models allow the prediction of grain size and recrystallized fractions into the workpiece during heating and forging operations.

- Included press and equipment kinematics: hydraulic press, hammer, counter blow hammer, knuckle joint press, mechanical press, multi-speed hydraulic press, screw press, link drive press.

- Die analysis: prediction of abrasive wear, stress distribution, thermal distribution. Coupled analysis into the dies during the part’s simulation.

- Optimization: fully automatic optimization tool, including CAD system coupling feature, for initial billet weight reduction, for die analysis, as well as process parameters. identification like material data (anisotropic coefficient for example), friction coefficient, Heat Transfer Coefficient…

- Computation time: best parallel speed-up.

- Chaining of all the forming operations and related operations (cutting, heat treatment)

Finisher simulation of a crankshaft. Tracking of the central looseness zone (area marked in red)

Blocker and finisher operation simulation of an automotive steering knukle (Courtesy of CDP Bharat).