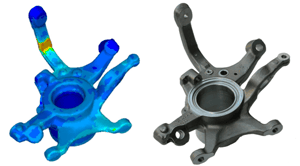

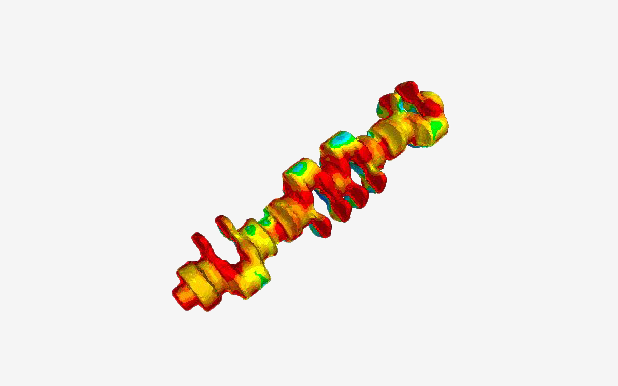

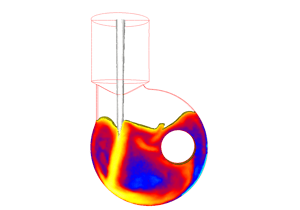

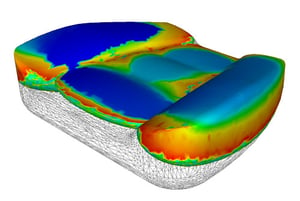

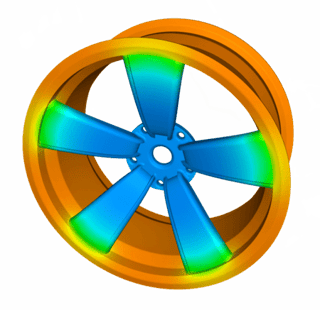

Transvalor proposes key solutions to design parts “first-time-right” and shorten the time to market. From the quote phase, benefit from a solid solution to predict your deformation sequences, anticipate the defaults and delete trials/errors. Reducing production costs, you benefit from numerous advantages to increase your return on investment.