New version of our forging simulation software, FORGE® NxT 3.0

From our users recommendations, we have developed and integrated new innovative features in FORGE® NxT 3.0, a version released in March 2019.

Please consult this article to learn more about our latest release FORGE® NxT 3.2 (January 2021).

What's new in FORGE® NxT 3.0?

Among the main features and improvements of this version, FORGE® NxT 3.0 includes:

- Improvement of computation time: Many improvements have been made at different levels, allowing the reduction of CPU time:

- Improvement of mesh quality

- Computation time of sensors divided by 8: Ideal for projects with many sensors, particle transport ...

- Acceleration of partitioning: Computation time of partitioning reduced to 90% (on average)

- Enhancement of the mesh adaptation: More accurate meshing especially in contact zones and for the shape of the part after cutting, for a similar number of nodes.

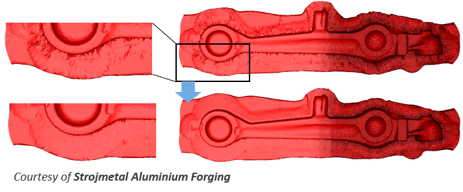

- Improvement of cutting and shearing processes: The cutting surface is cleaned and smoothed and then, transferred to the subsequent chain of simulations, without mesh problems resulting from cutting.

- New analysis models for heat treatment of aluminium alloys. Read more

- For quenching : Quench Factor Analysis (QFA) standard (for fast quenching) and improved Quench Factor Analysis (for slow quenching)

- For artificial aging : Shercliff-Ashby model enables to simulate the precipitation hardening treatment of aluminium alloys.

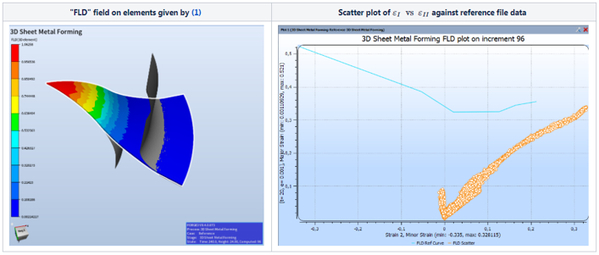

- Introduction of forming limit diagrams: The analysis of the deformation state of thin metal sheets has been improved and it is now possible to determine the risk of cracks.

Forming limit diagram

Forming limit diagram

- Supplied quench curves: Thermal exchanges and their variations during quenching are better considered and better expressed thanks to the generation of curves of drasticity. To get these curves, a material database of our scientific partner Quaker Houghton has been integrated. Each file is provided with its description and comparison with the experimental curves.

- Management of multi-materials interfaces: The interfaces between each layer are generated with more precision for 2D but also for 3D.

- Simplified results transfer from THERCAST® to FORGE®: In order to simplify the interoperability between software (e. g. porosity fraction, macrosegregation map), FORGE® automatically detects data from THERCAST® files when they are imported into FORGE®.

- Implementation of electrically assisted processes:

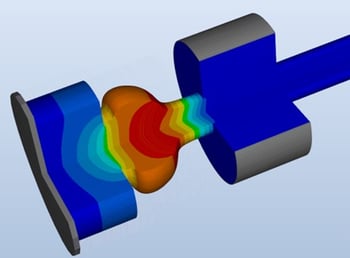

- Electrical upsetting process : Possibility to simulate in 2D and in 3D Read more

- Magnetic Pulse Forming: Consideration of Lorentz forces

- Introduction of a computation manager: This new system enables you to manage the launching of several simulations into a batch. You will now be able to use the interface to define your user solvers or your remote machines and clusters.

If you wish to get a quote or have any question,

please contact us at sales@transvalor.com or on the link below: