THERCAST® is a 3D finite-element software for foundry processes, continuous casting and ingot casting processes.

The software makes it possible to quickly and accurately analyze your manufacturing process, from the initial casting to the end of solidification. Thus, you anticipate manufacturing defects allowing you to produce high-quality components and reduce the prototyping phase.

In extremely competitive and ever-changing markets, simulation is now an essential step in the development cycle of high-value cast parts.

THERCAST® offers a complete and modular solution which will be able to provide you with valuable support for the production of ingots, castings or even continuous casting.

THERCAST® is your partner at every stage of your activity:

Thanks to a better understanding of physical phenomena, THERCAST® guarantees the feasibility of the part and limits non-quality costs by detecting casting defaults upstream.

THERCAST® also supports you in your engineering choices, in order to meet the needs expressed by your customers but also in a continuous improvement approach by optimizing existing productions.

Finally, choosing THERCAST® means capitalizing on your know-how within your company.

KEY ADVANTAGES TO OUTPERFORM YOUR COMPETITION

• Calculation ‘by slice’ to reduce computation time

• For fine analysis, a complete thermo-mechanical calculation over the entire metallurgical length

• Control of the liquid fraction zone and the position of the liquid well

• Anticipation of solidified thickness in primary and secondary cooling areas to avoid bulging defects or risks of piercing

• Assessment of the rate of deformation required to ensure the sealing of porosities

• For a better understanding of defects, the calculation of ‘fluid mechanics’ and ‘solid mechanics ‘ is coupled

THERCAST® integrates liquid/solid thermomechanical coupling involved in material transformation. With this implementation, you can study all types of phenomena: ladle and tundish flow, primary and secondary cooling, deformation in contact with rollers and spray-induced cooling.

THERCAST® offers a multilingual graphical interface and a business-oriented work environment. The software includes simulation templates with object lists or predefined process parameters. You can customize these models to fit your fabrications and your in-house terminology.

THERCAST® offers a graphical module dedicated to the material specifications representing the thermo-physical data and the associated laws of behavior. From the materials module, manually adjust the curves of the material parameters on the graph.

Use the periodic table of elements to create the macro-microsegregation data for your custom alloy or import the material datasheets from software based on the CALPHAD method.

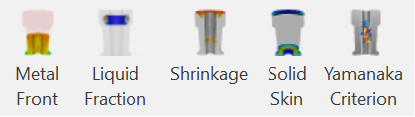

With THERCAST®, enjoy features that facilitate analysis, interpretation and dissemination of results such as ’Custom Actions’ to display in a single click your most important or most common results (e.g. metal front, porosity, etc.) or saving your workspace to obtain the same visual environment next time you run the software. Thus, the setup and result analysis steps are greatly facilitated.

DISCOVER THE LATEST FUNCTIONALITIES >

Custom actions available in THERCAST® software

Transvalor offers a wide range of software to simulate the entire manufacturing chain.

Start by simulating ingot casting in THERCAST® and continue your analysis in FORGE® to study open-die forging and control the rate of porosity closure. With SIMHEAT® software, you can also simulate heat treatments applied to the castings.

Transvalor’s ’End-to-End’ solution ensures perfect interoperability between its software applications with simple, fast data transfer and no loss of results accuracy.

.jpg?length=500&name=industrie_automobile1-(1).jpg)

To contribute to weight lightening of automotive parts made of aluminium alloys, our software integrates a foundry process modeling solution that meets the needs of the largest players in the automotive market, known for their performance requirements.

Thanks to a faithful representation of continuous casting machines configuration, THERCAST® offers a unique and precise solution to meet the challenges associated with profile manufacturing.

.jpg?length=500&name=industrie_side%CC%81rurgie%20(1).jpg)

With its module devoted to ingot casting, THERCAST® software is the favored partner of steelmakers seeking to optimize their ingot manufacturing processes.

Validate the dimensioning of a new ingot shape.

A validation process for dimensioning a 10-ton ingot was implemented and numerically certified prior to ingot manufacture with THERCAST® software.

"Thanks to THERCAST® software, we were able to confidently propose a new ingot geometry to steel mill crews. The characterizations that were done on the product confirmed these predictions."

This phenomenon is particularly significant for investment casting or for cluster casting of small/medium-sized ingot or simply for castings with concave shapes.

As soon as shrinkage appears, the software takes into account the influence of the air gap thus created and locally adapts the heat exchange between the metal and the mold.

The software includes a self-adaptive remeshing solution that improves accuracy and computation time. This feature allows the modeling of turbulent flows but also the accurate detection of defects and their propagation.

At each instant of the THERCAST® process performs thermomechanical resolution coupled both in the room and in the molds.

World leader in software for simulation of material forming processes.